Stamping hardware yog ib feem nrog tej yam zoo li, qhov loj thiab kev ua tau zoo tau los ntawm cov txheej txheem stamping.Stamping hardware yog dav siv nyob rau hauv aerospace, tsheb, shipbuilding, machinery, tshuaj thiab lwm yam liaj teb, thiab tau maj mam dhau los ua ib feem tseem ceeb ntawm tam sim no qhov chaw tsim kev lag luam.Cov txheej txheem stamping raug cuam tshuam los ntawm peb yam: cov khoom siv, cov khoom siv ua haujlwm thiab cov roj ua haujlwm.Cov hauv qab no yog cov lus qhia luv luv ntawm cov teeb meem tshwm sim ntawm cov txheej txheem kho vajtse stamping los ntawm MINGXING Petrochemical:

1, Kev zoo ntawm cov hlau stamping

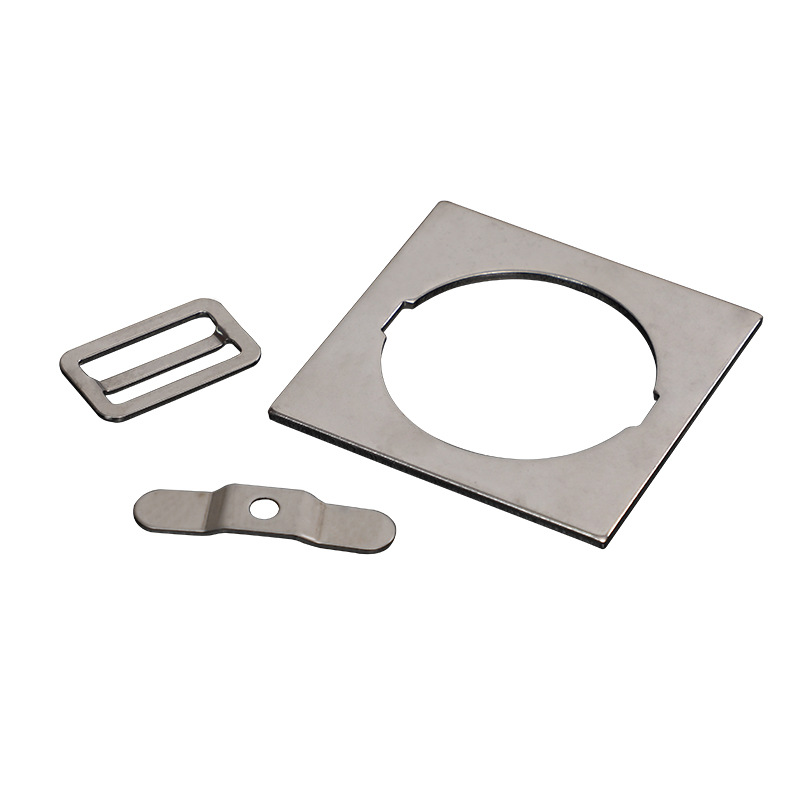

(1) Cov hlau stamping qhov chaw yog tsim los ntawm stamping ntawm qhov chaw ntawm cov ntaub ntawv siv tsawg.Lawv cov khoom yog lub teeb hauv qhov hnyav thiab zoo hauv rigidity.Tom qab cov ntawv hlau dhau los ntawm cov yas deformation, cov qauv txheej txheem hauv cov hlau tau zoo tuaj, thiab lub zog ntawm cov khoom stamping tau zoo tuaj.

(2) Hardware stamping qhov chaw muaj qhov tseeb qhov tseeb, zoo ib yam thiab qhov ntev ntawm tib lub module, thiab kev sib hloov tau zoo.Cov cuab yeej siv dav dav thiab cov ntawv thov tuaj yeem txaus siab yam tsis muaj kev siv tshuab ntxiv.

(3) Thaum lub sij hawm stamping txheej txheem, vim hais tias cov tsos ntawm cov ntaub ntawv tsis puas, nws muaj zoo zoo zoo thiab zoo nkauj tsos, uas muab yooj yim tej yam kev mob rau nto painting, electroplating, phosphating thiab lwm yam nto kho.

2 、 Cov khoom xaiv ntawm hlau stamping

Muaj peb lub ntsiab stamping txheej txheem: blanking, dabtsi yog khoov thiab ncab.Cov txheej txheem sib txawv muaj cov kev xav tau sib txawv rau cov phaj.Kev xaiv ntawm cov ntaub ntawv tseem yuav tsum tau txiav txim siab raws li qhov kwv yees ntawm cov khoom thiab kev siv tshuab.

(1) Blanking xav kom lub phaj yuav tsum muaj cov yas txaus los xyuas kom meej tias lub phaj tsis tawg thaum lub blanking.Cov khoom muag muag muaj qhov ua tau zoo blanking, thiab cov khoom ua haujlwm nrog cov seem du thiab me me inclination tuaj yeem tau txais tom qab blanking;Qhov zoo ntawm cov ntaub ntawv nyuaj tom qab blanking yog qhov tsis zoo, thiab cov seem tsis sib xws yog loj, tshwj xeeb tshaj yog rau cov phaj tuab.Rau cov ntaub ntawv nkig, tearing yog ib qho yooj yim tshwm sim tom qab blanking, tshwj xeeb tshaj yog thaum qhov dav me me heev.

(2) Cov phaj yuav tsum khoov yuav tsum muaj cov yas txaus thiab tsis muaj kev txwv.Lub phaj nrog high plasticity tsis yooj yim rau tawg thaum khoov.Lub phaj nrog qis qis qis thiab qis dua elastic modulus muaj me me rebound deformation tom qab khoov, thiab nws yog ib qho yooj yim kom tau txais cov duab khoov nrog qhov loj me.Cov khoom uas muaj brittleness ntau dua yuav tsum muaj qhov sib txawv loj dua qhov sib txawv ntawm qhov sib txawv thaum khoov, txwv tsis pub nws yooj yim tawg thaum khoov.

(3) Kev kos duab ntawm cov ntawv hlau, tshwj xeeb tshaj yog cov duab sib sib zog nqus, yog ib qho nyuaj dua hauv cov txheej txheem ua cov ntawv hlau.Nws tsis tsuas yog yuav tsum tau kos duab qhov tob kom me me raws li qhov ua tau, cov duab ua kom yooj yim thiab du raws li qhov ua tau, tab sis kuj xav tau cov khoom siv kom muaj cov yas zoo, txwv tsis pub nws yooj yim heev los ua kom tag nrho cov distortion ntawm ib feem, hauv zos. wrinkling, thiab txawm lub tensile tawg ntawm daim duab.

3 、 Kev xaiv roj rau hlau stamping

Cov roj stamping ua lub luag haujlwm tseem ceeb hauv cov txheej txheem stamping, thiab kev ua haujlwm txias txias thiab kev ua haujlwm siab thiab kev hnav tsis zoo tau ua rau muaj txiaj ntsig zoo hauv kev pab cuam lub neej ntawm kev tuag thiab kev txhim kho ntawm cov khoom ua haujlwm raug.Raws li cov khoom sib txawv ntawm lub workpiece, kev ua haujlwm ntawm cov roj stamping kuj txawv thaum xaiv.

(1) Silicon steel phaj yog cov khoom siv yooj yim rau xuas nrig ntaus.Feem ntau, rau lub hom phiaj ntawm kev ua haujlwm tu, tsis tshua muaj viscosity xuas nrig ntaus cov roj yuav raug xaiv ntawm qhov chaw tiv thaiv kev xuas nrig ntaus burr.

(2) Thaum xaiv cov roj stamping rau cov pa roj carbon steel phaj, qhov viscosity zoo dua yuav tsum raug txiav txim siab raws li cov txheej txheem nyuaj, txoj kev kos cov roj thiab degreasing.

(3) Vim yog cov tshuaj tiv thaiv ntawm galvanized steel ntawv thiab chlorine series additives, yuav tsum tau them nyiaj mloog mus rau qhov muaj peev xwm ntawm dawb xeb ntawm chlorine hom stamping roj thaum xaiv cov roj stamping rau galvanized steel ntawv, thiab siv MINGXING sulfur hom stamping roj tuaj yeem zam qhov teeb meem xeb, tab sis nws yuav tsum tau degreased sai li sai tau tom qab stamping.

(4) Stainless hlau phaj yog ib yam khoom uas yooj yim rau harden, yog li nws yuav tsum tau siv cov roj zaj duab xis siab zog thiab anti-sintering tensile roj.Feem ntau, stamping roj uas muaj leej faj thiab chlorine compound additives yog siv los xyuas kom meej qhov kev ua haujlwm siab thiab tsis txhob burr, tawg thiab lwm yam teeb meem ntawm lub workpiece.

Cov no yog cov yam ntxwv uas cuam tshuam rau qhov zoo ntawm cov hlau stamping qhov chaw.Nrog rau txoj kev loj hlob sai ntawm precision stamping technology, me me stamping qhov chaw tuaj yeem ua tau raws li qhov xav tau ntawm ntau hom tshuab cuab yeej, cov khoom siv hluav taws xob, cov cuab yeej thiab lwm yam kev lag luam.MINGXING yog ib qho kev tshawb fawb thiab kev loj hlob hauv paus rau high-end metalworking pab.Tus kheej tsim cov roj stamping muaj kev ua haujlwm zoo heev thiab tiv thaiv kev hnav, tuaj yeem tiv thaiv kev tuag zoo, txhim kho kev ua haujlwm zoo, thiab txuas ntxiv lub neej kev pabcuam ntawm cov khoom siv.Nws yog tus tsim tus khub ntawm ntau lub tshuab loj thiab nruab nrab cov cuab yeej cuab yeej cuab tam hauv Suav teb, thiab tau txais kev lees paub dav dav thiab kev qhuas siab hauv kev lag luam.

Post lub sij hawm: Feb-16-2023