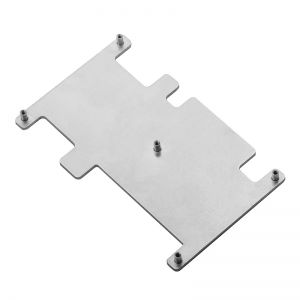

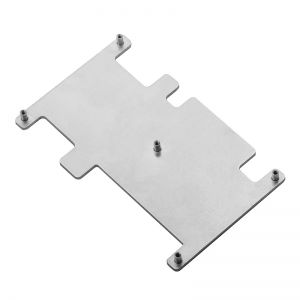

| Khoom muaj | C1100, T2, Bronze, tooj dag, tooj liab alloy, aluminium alloy, tin plated, npib tsib xee nyiaj |

| Kev kho saum npoo | zinc / nickel / chrome / tin plating (xim lossis ntuj), Galvanization, anodizing, roj txau, hmoov txheej, polishing, passivate, txhuam, hlau kos duab, pleev xim, thiab lwm yam. |

| Cov txheej txheem hlau muaj | Tooling, Prototype, Txiav, Stamping, Vuam, Tapping, dabtsi yog khoov thiab sib sau, Machining, nto kho, sib dhos |

| Specification | OEM / ODM, raws li tus neeg siv khoom kos duab lossis qauv |

| Daim ntawv pov thawj | ISO9001: 2015 / IATF 16949 / SGS / RoHS |

| Ua siab ntev | 0.02mm-0.1 hli |

| Software | Auto CAD, Soliworks, PDF |

| Daim ntawv thov | Automotive qhov chaw, tsheb ciav hlau qhov chaw, kho mob qhov chaw, marine qhov chaw, teeb pom kev zoo qhov chaw, twj tso kua mis lub cev, valve qhov chaw, architectural qhov chaw thiab rooj tog zaum, thiab lwm yam. |

Kev Cai Hlau Stamping Services

Hlau Stampingyog cov txheej txheem ntawm muab cov ntawv tiaj tus hlau nyob rau hauv daim ntawv dawb los yog coil rau hauv lub xovxwm stamping qhov twg lub cuab yeej thiab tuag saum npoo tsim cov hlau rau hauv cov duab zoo.Hlau Stamping muaj xws li ntau yam ntawm cov ntawv hlau tsim cov txheej txheem, xws li xuas nrig ntaus siv lub tshuab xovxwm lossis stamping xovxwm, blanking, embossing, dabtsi yog khoov, flanging, thiab npib.Qhov no tuaj yeem yog ib theem kev ua haujlwm uas txhua qhov mob stroke ntawm cov xovxwm tsim cov ntawv xav tau ntawm lubdaim ntawv hlau, los yog tuaj yeem tshwm sim los ntawm ntau theem.

Vim li cas thiaj xaiv peb?

Mingxing yog ITAF-certified thiab ISO 9001-certified, yog li peb cov neeg tuaj yeem tso siab rau kev nyab xeeb thiab zoo ntawm peb.stamped khoom.Rau ntau tshaj 24 xyoo, peb lub tuam txhab tau tsim thiab tsim cov rooj sib txoos, kev cai hlau stamping qhov chaw, thiab lwm yam.Peb muaj cov chaw tsim khoom zoo rau kev tsim cov khoom lag luam zoo nrog cov cuab yeej siv niaj hnub thiab cov txheej txheem ua haujlwm zoo tshaj plaws.

Ntawm Mingxing, peb lub peev xwm rau kev cai tooj liab busbars suav nrog:

1. Kev ua raws li RoHS

2.Barrel thiab khib Plating

3. Cov lus qhia xaiv cov khoom

4. Progressive Tuag Stamping

5. Kev xa khoom sai sai

6. Tsim thiab sib dhos

7. Kev Pabcuam Prototyping

FAQ

Q: Koj xav tau dab tsi los muab nqe lus?

A: Nws yuav ua haujlwm rau peb yog tias koj muaj kev kos duab ntawm cov khoom, peb yuav xa peb qhov zoo tshaj plaws rau koj raws li koj daim duab kos.

Tab sis nws zoo rau peb yog tias koj tsis muaj daim duab kos, peb lees txais cov qauv, thiab peb tus kws tshaj lij engineers tuaj yeem hais raws li koj cov qauv.

Q: Koj puas muab cov qauv?Puas yog dawb lossis ntxiv?

A: Cov qauv dawb yog muaj.

Q: Koj cov nqe lus them nqi yog dab tsi?

A: 30% them rau kev pib ua khoom loj thiab 70% tshuav nyiaj them thaum pom daim B / L.

Q: Koj yuav ua li cas rau kev pab cuam tom qab muag?

A: Thaum peb cov khoom siv hlau siv rau koj cov khoom, peb yuav ua raws thiab tos koj cov lus qhia.

Yog tias xav tau kev pab ntawm kev sib dhos lossis lwm yam teeb meem, peb tus kws tshaj lij engineer yuav muab cov kev daws teeb meem zoo tshaj plaws rau koj.

-

Zinc Plated lossis Plain DIN 125 Steel Flat Washers

-

Aluminium tshav kub dab dej rau BMS 48V 65A 13s Lithium ...

-

Sheet Hlau Fabrication Services rau Aluminium a ...

-

Tuam Tshoj OEM Service Sheet Hlau Stamping Part

-

High-Quality Precision Hlau Stamping Chaw tsim tshuaj paus ...

-

Aluminium extrusion anodizing dab dej rau bms, ...