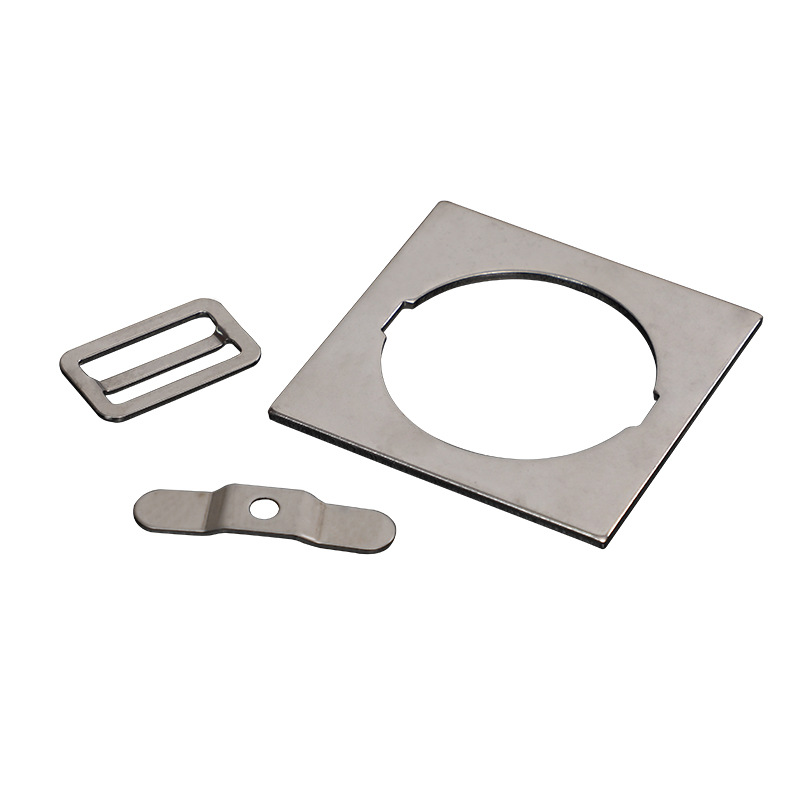

Kayan aikin hatimi wani sashi ne mai takamaiman tsari, girma da aiki da aka samu ta hanyar yin hatimi.Ana amfani da kayan hatimi sosai a sararin samaniya, mota, ginin jirgi, injina, sinadarai da sauran fannoni, kuma sannu a hankali ya zama wani muhimmin sashi na masana'antar kera sassa na yanzu.Tsarin stamping yana shafar abubuwa uku: nau'in kayan aiki, kayan aiki da aikin mai.Mai zuwa shine taƙaitaccen gabatarwar matsalolin gama gari na tsarin tambarin kayan masarufi ta MINGXING Petrochemical:

1. Fasaha abũbuwan amfãni daga karfe stamping

(1) Ana ƙera sassan ƙarfen tambarin ƙarfe ta hanyar yin tambari akan yanayin ƙarancin amfani da bayanai.Sassan su suna da nauyi a nauyi kuma suna da kyau a cikin rigidity.Bayan da takardar takarda ta wuce ta hanyar nakasar filastik, tsarin tsari a cikin karfe yana inganta, kuma an inganta ƙarfin sassa na stamping.

(2) Sassan hatimin kayan masarufi suna da daidaiton girman girma, iri ɗaya da na gama-gari na module iri ɗaya, da kyakkyawar musanyawa.Za a iya gamsu da na'urar gabaɗaya da buƙatun aikace-aikacen ba tare da ƙarin injina ba.

(3) A lokacin aiwatar da stamping, saboda bayyanar bayanan ba ta lalace ba, yana da kyakkyawan bayyanar da kyau da kyau, wanda ke ba da yanayi masu dacewa don zane-zane, electroplating, phosphating da sauran jiyya.

2. Material selection na karfe stamping

Akwai manyan matakai uku na stamping: blanking, lankwasawa da mikewa.Daban-daban matakai suna da buƙatu daban-daban don faranti.Hakanan ya kamata a yi la'akari da zaɓin kayan bisa ga kusan sifar samfuran da fasahar sarrafawa.

(1) Blanking yana buƙatar cewa farantin ya kamata ya kasance da isasshen filastik don tabbatar da cewa farantin ba ya tsage yayin blanking.Kayan abu mai laushi yana da kyakkyawan aiki na blanking, kuma ana iya samun aikin aiki tare da sashe mai santsi da ƙananan sha'awa bayan blanking;Ingancin kayan wuya bayan blanking ba shi da kyau, kuma sashin rashin daidaituwa yana da girma, musamman ga faranti mai kauri.Don kayan da ba su da ƙarfi, yaga yana da sauƙin faruwa bayan ɓarna, musamman lokacin da faɗin ya yi ƙanƙanta.

(2) Faranti da za a tanƙwara za su sami isasshen filastik da ƙarancin yawan amfanin ƙasa.Farantin tare da babban filastik ba sauƙin fashe lokacin lanƙwasa ba.Farantin tare da ƙananan yawan amfanin ƙasa da ƙananan modules na roba yana da ƙananan nakasar sake dawowa bayan lankwasawa, kuma yana da sauƙi don samun siffar lanƙwasawa tare da madaidaicin girman.Kayan da ya fi girma dole ne ya sami radius mafi girma na dangi lokacin lankwasawa, in ba haka ba yana da sauƙi a fashe yayin lanƙwasawa.

(3) Zane karfen takarda, musamman zane mai zurfi, yana daya daga cikin abubuwan da suka fi wahala wajen sarrafa karafa.Ba wai kawai yana buƙatar zurfin zane ya zama ƙarami kamar yadda zai yiwu ba, siffar ya zama mai sauƙi da sauƙi kamar yadda zai yiwu, amma kuma yana buƙatar kayan aiki don samun filastik mai kyau, in ba haka ba yana da sauƙi don haifar da ɓarna gaba ɗaya na ɓangaren, na gida. wrinkling, har ma da tsagewar ɓangaren zane.

3. Oil selection for karfe stamping

The stamping man taka muhimmiyar rawa a cikin stamping tsari, da kuma mai kyau sanyaya yi da matsananci matsa lamba da anti-wear yi sun yi wani m tsalle a cikin sabis rayuwa na mutuwa da kuma inganta workpiece daidaito.Dangane da nau'ikan kayan aiki daban-daban, aikin mai hatimi shima ya bambanta lokacin zaɓin.

(1) Silicon karfe farantin karfe ne in mun gwada da sauki abu don naushi.Gabaɗaya, don manufar tsabtace kayan aiki, za a zaɓi ɗanɗano mai ƙarancin danko akan yanayin hana buguwa.

(2) Lokacin zabar man fetur don farantin karfe na carbon, za a ƙayyade mafi kyawun danko bisa ga wahalar aiwatarwa, hanyar zana samar da man fetur da lalata.

(3) Saboda da sinadaran dauki tsakanin galvanized karfe takardar da chlorine jerin Additives, da hankali ya kamata a biya ga yiwuwar farin tsatsa na chlorine irin stamping mai a lokacin da zabi da stamping man ga galvanized karfe takardar, da kuma yin amfani da MINGXING sulfur irin stamping. man zai iya guje wa matsalar tsatsa, amma ya kamata a rage shi da wuri-wuri bayan an yi tambari.

(4) Bakin karfe farantin karfe abu ne mai sauƙi don taurara, don haka ana buƙatar amfani da ƙarfin fim ɗin mai mai ƙarfi da man mai mai karewa.Gabaɗaya, ana amfani da hatimin mai da ke ɗauke da sulfur da abubuwan daɗaɗɗen chlorine don tabbatar da matsanancin matsin lamba da gujewa burr, fasa da sauran matsalolin aikin.

Waɗannan su ne abubuwan da ke shafar ingancin sassan ƙarfe na stamping.Tare da saurin haɓaka fasahar hatimi daidaitattun ƙima, ƙananan sassa na stamping na iya biyan buƙatun nau'ikan kayan aikin injin iri-iri, na'urorin lantarki, kayan aiki da sauran masana'antun masana'antu.MINGXING tushe ne na bincike da haɓaka don manyan kayan aikin ƙarfe na ƙarshe.Man da aka haɓaka mai zaman kansa yana da matuƙar matsananciyar matsa lamba da aikin rigakafin sawa, yana iya kare mutuƙar yadda ya kamata, haɓaka inganci sosai, da tsawaita rayuwar kayan aikin.Ya zama abokin tarayya da aka keɓe na manyan masana'antun kayan aikin injina da yawa a cikin Sin, kuma ya sami karɓuwa sosai da babban yabo a masana'antar.

Lokacin aikawa: Fabrairu-16-2023