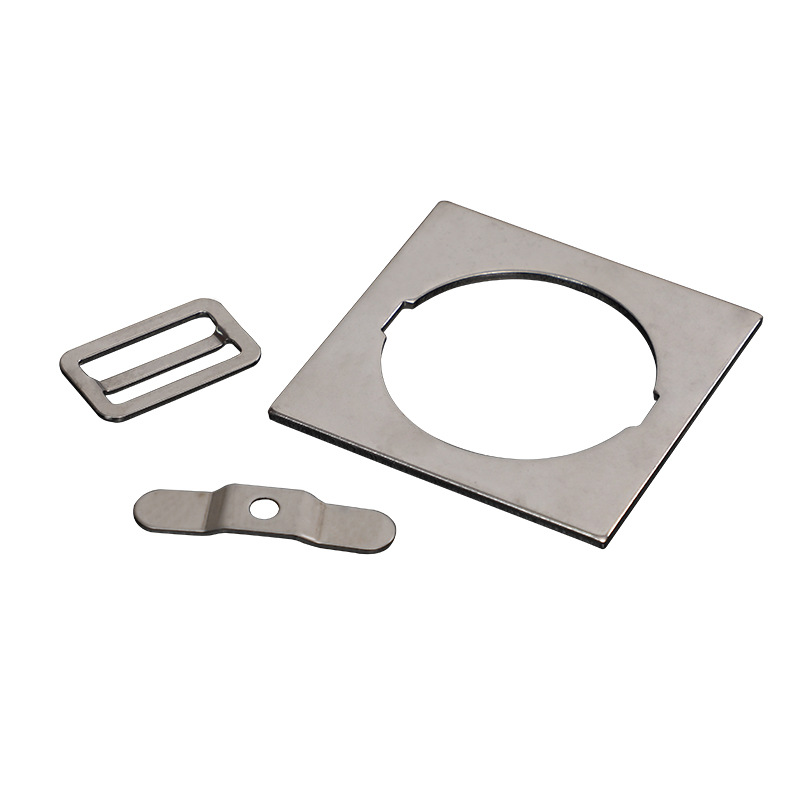

I-hardware ye-stamping yinxalenye enemilo ethile, ubungakanani kunye nokusebenza okufunyenwe ngenkqubo yesitampu.I-hardware yesitampu isetyenziswa kakhulu kwi-aerospace, imoto, ukwakha iinqanawa, oomatshini, iikhemikhali kunye namanye amasimi, kwaye ngokuthe ngcembe ibe yinxalenye ebalulekileyo yoshishino lwangoku lokuvelisa.Inkqubo yesitampu ichaphazeleka zizinto ezintathu: uhlobo lwezixhobo, izinto zokusebenza kunye nokusebenza kweoli.Oku kulandelayo yintshayelelo emfutshane yeengxaki eziqhelekileyo zenkqubo yesitampu sehardware nguMINGXING Petrochemical:

I-1, izibonelelo zeTekhnoloji zesitampu sesinyithi

(1) Iindawo zesitampu zentsimbi zenziwe ngokunyathela kwindawo yokusetyenziswa kwedatha ephantsi.Amalungu abo alula ngobunzima kwaye alungile ngokungqongqo.Emva kokuba i-sheet metal idlula kwi-deformation yeplastiki, isakhiwo sokucwangciswa ngaphakathi kwesinyithi siphuculwe, kwaye amandla eengxenye zesitampu aphuculwe.

(2) Amacandelo e-Hardware stamping ane-high dimensional ichanekile, iyunifomu kunye nemilinganiselo eqhelekileyo yemodyuli efanayo, kunye nokutshintshiselana okulungileyo.Isixhobo jikelele kunye neemfuno zesicelo zinokwaneliswa ngaphandle komatshini ongezelelweyo.

(3) Ngethuba lenkqubo yesitampu, ngenxa yokuba ukubonakala kwedatha akukonakali, inomgangatho wembonakalo entle kunye nembonakalo entle, ebonelela ngeemeko ezifanelekileyo zokupeyinta komphezulu, i-electroplating, i-phosphating kunye nolunye unyango lomhlaba.

2, Ukukhethwa kwezinto eziphathekayo zesitampu sesinyithi

Kukho iinkqubo ezintathu eziphambili zokutywina: ukuvala, ukugoba kunye nokuzolula.Iinkqubo ezahlukeneyo zineemfuno ezahlukeneyo zamacwecwe.Ukukhethwa kwezixhobo kufuneka kwakhona kuthathelwe ingqalelo ngokwemilo eqikelelweyo yeemveliso kunye neteknoloji yokucubungula.

(1) Ukungaxutywanga kufuna ukuba ipleyiti ibe neplastiki eyaneleyo ukuze kuqinisekiswe ukuba ipleyiti ayiqhekeki ngexesha lokugquma.Izinto ezithambileyo zinomsebenzi olungileyo wokuvala, kwaye i-workpiece enecandelo eligudileyo kunye nokuthambekela okuncinci kunokufumaneka emva kokuvala;Umgangatho wezinto eziqinileyo emva kokugubungela umbi, kwaye ukungalingani kwecandelo kukhulu, ngakumbi kwiipleyiti ezishinyeneyo.Kwizinto ezinqabileyo, ukukrazula kulula ukwenzeka emva kokugqoka, ngakumbi xa ububanzi buncinci kakhulu.

(2) Iipleyiti eziza kugotywa ziya kuba neplastiki eyaneleyo kunye nomda wesivuno esiphantsi.Ipleyiti eneplastiki ephezulu akulula ukuyiqhekeza xa igoba.Ipleyiti enomda wesivuno esisezantsi kunye nemodyuli esezantsi yeelastiki ine-deformation encinci ye-rebound emva kokugoba, kwaye kulula ukufumana imilo yokugoba ngobungakanani obuchanekileyo.Izinto eziphathekayo ezinobunzima obukhulu kufuneka zibe neradiyasi enkulu yokugoba xa igoba, ngaphandle koko kulula ukuqhekeka ngexesha lokugoba.

(3) Umzobo we-sheet metal, ngakumbi umzobo onzulu, yenye yezona ndawo zinzima kakhulu kwinkqubo yokucubungula isinyithi.Akufuneki kuphela ukuba ubunzulu bomzobo bube buncinci ngokusemandleni, ubume bube bulula kwaye bugudileyo ngokunokwenzeka, kodwa bufuna ukuba izinto eziphathekayo zibe neplastiki enhle, ngaphandle koko kulula kakhulu ukubangela ukuphazamiseka ngokubanzi kwenxalenye, yendawo. ukushwabana, kunye nokuqhekeka okuqinileyo kwenxalenye yomzobo.

3, Ukukhetha i-oyile yesitampu sesinyithi

I-oyile yesitampu idlala indima ephambili kwinkqubo yesitampu, kwaye ukusebenza kakuhle kokupholisa kunye noxinzelelo olunzima kunye nokusebenza okuchasene nokunxiba kwenze ukutsiba okusemgangathweni kubomi benkonzo yokufa kunye nokuphuculwa kokuchaneka kwe-workpiece.Ngokwezinto ezahlukeneyo ze-workpiece, ukusebenza kweoli ye-stamping ikwahluke xa ukhetha.

(1) Ipleyiti yensimbi ye-silicon yinto elula kakhulu ukuyibetha.Ngokuqhelekileyo, ngenjongo yokucoca i-workpiece, i-viscosity punching oil ephantsi iya kukhethwa kwindawo yokukhusela i-punching burr.

(2) Xa ukhetha i-oyile ye-stamping ye-carbon steel plate, i-viscosity engcono iya kugqitywa ngokuhambelana nobunzima benkqubo, indlela yokudweba ukunikezelwa kweoli kunye nokunciphisa.

(3) Ngenxa yokusabela kwekhemikhali phakathi kweshiti lentsimbi ekhandisiweyo kunye nezongezo zochungechunge lweklorini, ingqalelo kufuneka ihlawulwe kwi-rust emhlophe yohlobo lwe-oyile yokunyathela i-oyile xa ukhetha i-oyile yesitampu ye-galvanized sheet sheet, kunye nokusetyenziswa kwe-MINGXING sulfur type stamping. ioyile inokunqanda ingxaki yomhlwa, kodwa kufuneka ithotywe igrisi ngokukhawuleza emva kokunyathela.

(4) Ipleyiti yensimbi engenasici yinto ekulula ukuyenza lukhuni, ngoko ke kufuneka kusetyenziswe amandla efilimu yeoli ephezulu kunye ne-anti-sintering tensile oil.Ngokubanzi, isitampu seoyile equlethe izongezo zesulfure kunye neklorini isetyenziselwa ukuqinisekisa ukusebenza koxinzelelo olugqithisileyo kunye nokuphepha i-burr, i-crack kunye nezinye iingxaki ze-workpiece.

Ezi zizinto ezichaphazela umgangatho wamacandelo e-metal stamping.Ngophuhliso olukhawulezayo lwetekhnoloji yesitampu esichanekileyo, iinxalenye ezincinci zesitampu zinokuhlangabezana neemfuno zeentlobo ezahlukeneyo zezixhobo zoomatshini, izixhobo zombane, izixhobo kunye namanye amashishini okuvelisa.I-MINGXING sisiseko sophando kunye nophuhliso lwezixhobo eziphezulu zesinyithi.I-oyile yesitampu ephuhliswe ngokuzimeleyo inoxinzelelo olugqithisileyo kunye nokusebenza okuchasene nokunxiba, inokukhusela ngokufanelekileyo ukufa, ukuphucula kakhulu ukusebenza kakuhle, kunye nokwandisa ubomi benkonzo yezixhobo.Liqabane elichongiweyo lamashishini amaninzi amakhulu kunye naphakathi kwezixhobo zoomatshini eTshayina, kwaye liphumelele ukuqatshelwa okubanzi kunye nendumiso ephezulu kushishino.

Ixesha lokuposa: Feb-16-2023