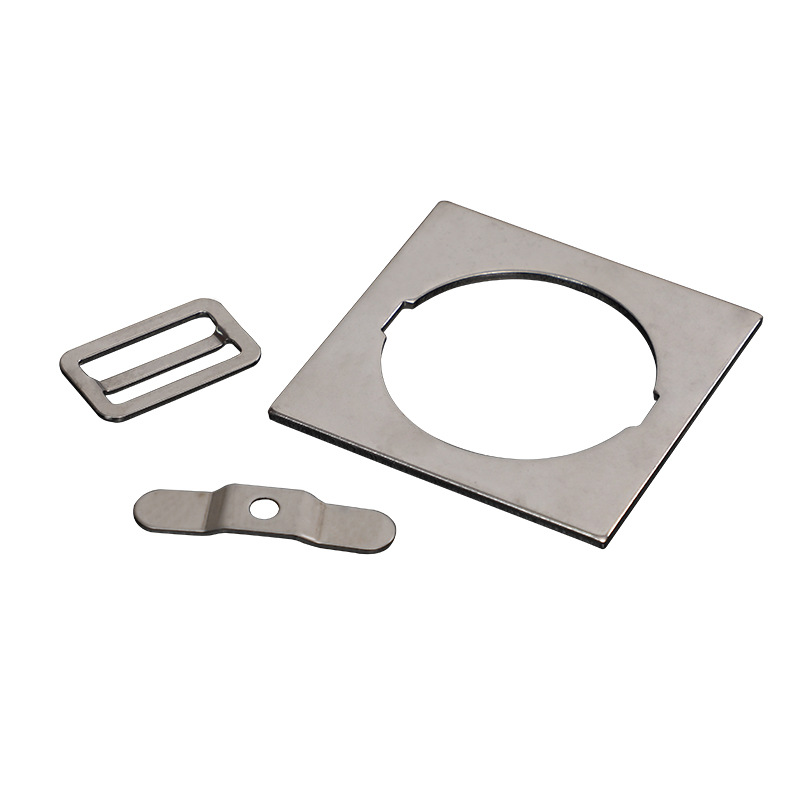

He ʻāpana me kekahi ʻano, ka nui a me ka hana i loaʻa ma ke kaʻina hana stamping.Hoʻohana nui ʻia ʻo Stamping hardware i ka aerospace, kaʻa, hana moku, mīkini, kemika a me nā māla ʻē aʻe, a ua lilo i mea nui o ka ʻoihana hana ʻāpana o kēia manawa.Hoʻopili ʻia ke kaʻina hana stamping e nā kumu ʻekolu: ʻano mea hana, mea hana a me ka hana ʻaila.ʻO kēia ka hōʻike pōkole o nā pilikia maʻamau o ke kaʻina hana stamping hardware e MINGXING Petrochemical:

1、 ʻO nā pono ʻenehana o ka hoʻopaʻa ʻana metala

(1) Hana ʻia nā ʻāpana stamping metala ma ke kahakaha ʻana ma ke kumu o ka hoʻohana haʻahaʻa haʻahaʻa.He maʻalahi ko lākou mau ʻāpana a maikaʻi i ka rigidity.Ma hope o ka hele ʻana o ka metala i ka deformation plastic, hoʻomaikaʻi ka hoʻonohonoho hoʻonohonoho ʻana i loko o ka metala, a hoʻomaikaʻi ʻia ka ikaika o nā ʻāpana stamping.

(2) Loaʻa i nā ʻāpana hoʻoheheʻe ʻana i nā ʻāpana kiʻekiʻe ke ʻano kiʻekiʻe, nā ʻano like ʻole a me nā ana maʻamau o ka module hoʻokahi, a me ka hoʻololi maikaʻi ʻana.Hiki ke hoʻokō ʻia ka mea maʻamau a me nā koi noiʻi me ka ʻole o ka mīkini ʻana.

(3) I ka wā o ka stamping kaʻina, no ka mea, ʻaʻole i hōʻino ʻia ke ʻano o ka ʻikepili, he maikaʻi kona hiʻohiʻona maikaʻi a me ka helehelena nani, e hāʻawi ana i nā kūlana kūpono no ka pena kiʻi, electroplating, phosphating a me nā ʻano lapaʻau ʻē aʻe.

2、 Ke koho ʻana i nā mea metala

ʻEkolu mau hana stamping nui: blanking, bending and stretching.Loaʻa i nā kaʻina hana like ʻole nā koi no nā papa.Pono e noʻonoʻo ʻia ke koho ʻana i nā mea e like me ke ʻano o nā huahana a me ka ʻenehana hana.

(1) Pono ka Blanking e lawa ka plasticity o ka pā e hōʻoia ai ʻaʻole nahā ka pā i ka wā o ka blanking.ʻO ka mea palupalu he hana blanking maikaʻi, a hiki ke loaʻa ka mea hana me ka ʻāpana maʻemaʻe a me ke ʻano liʻiliʻi ma hope o ka blanking;ʻAʻole maikaʻi ka maikaʻi o nā mea paʻakikī ma hope o ka hoʻopaʻa ʻana, a ʻoi aku ka nui o ka ʻāpana ʻole, ʻoi aku hoʻi no nā papa mānoanoa.No nā mea palupalu, maʻalahi ka haehae ʻana ma hope o ka pani ʻana, ʻoi aku ka liʻiliʻi o ka laulā.

(2) E lawa ka plasticity a me ka palena haʻahaʻa o nā papa e hoʻopiʻi ʻia.ʻAʻole maʻalahi ka pāpaʻi me ka plasticity kiʻekiʻe i ka wā e kulou ai.ʻO ka pā me ka palena haʻahaʻa haʻahaʻa a me ka modulus elastic haʻahaʻa he liʻiliʻi rebound deformation ma hope o ke kulou ʻana, a maʻalahi ka loaʻa ʻana o ke ʻano kulou me ka nui pololei.ʻO ka mea me ka brittleness ʻoi aku ka nui o ka radius pili pili i ka wā e kulou ai, i ʻole e maʻalahi ke pohā i ka wā e kulou ana.

(3) ʻO ke kaha kiʻi ʻana o ka pepa metala, ʻoi aku ka hohonu o ke kiʻi ʻana, ʻo ia kekahi o nā ʻāpana paʻakikī i ke kaʻina hana metala.ʻAʻole wale ia e koi i ka hohonu o ke kaha kiʻi e like me ka liʻiliʻi, ʻo ke ʻano e like me ka maʻalahi a me ka maʻalahi e like me ka hiki, akā pono nō hoʻi ka mea i loaʻa ka plasticity maikaʻi, i ʻole he mea maʻalahi loa ke kumu o ka distortion holoʻokoʻa o ka ʻāpana, kūloko. wrinkling, a me ka māwae tensile o ka māhele kaha kiʻi.

3、 Koho aila no ka hoʻopaʻa ʻana metala

He koʻikoʻi ko ka ʻaila stamping i ke kaʻina hana stamping, a ʻo ka hana hoʻoluʻu maikaʻi a me ke koʻikoʻi nui a me ka hana anti-wear i hana i kahi lele qualitative i ke ola lawelawe o ka make a me ka hoʻomaikaʻi ʻana i ka pololei o ka mea hana.Wahi a nā mea like ʻole o ka mea hana, ʻokoʻa ka hana o ka ʻaila stamping i ke koho ʻana.

(1) He mea maʻalahi ka pā kila silikoni no ke kuʻi ʻana.ʻO ka maʻamau, no ke kumu o ka hoʻomaʻemaʻe ʻana i ka mea hana, e koho ʻia ka aila punching haʻahaʻa ma ke kumu o ka pale ʻana i ka punching burr.

(2) Ke koho ʻana i ka ʻaila stamping no ka pā kila kalapona, e hoʻoholo ʻia ka viscosity maikaʻi e like me ka paʻakikī o ke kaʻina hana, ke ʻano o ka huki ʻana i ka aila a me ka degreasing.

(3) Ma muli o ka hopena kemika ma waena o ka galvanized steel sheet a me ka chlorine series additives, pono e uku ʻia i ka hiki ke hiki ke hoʻopaʻa ʻia ka ʻaila keʻokeʻo o ka ʻaila chlorine type i ke koho ʻana i ka aila hoʻopaʻa ʻia no ke kila kila, a me ka hoʻohana ʻana i ka MINGXING sulfur type stamping. hiki i ka aila ke pale aku i ka pilikia o ka rust, akā, pono e hoʻomaʻemaʻe koke ʻia ma hope o ke kuʻi ʻana.

(4) He mea maʻalahi ka paʻakikī paʻakikī, no laila pono e hoʻohana i ka ikaika kiʻiʻoniʻoni kiʻekiʻe a me ka ʻaila tensile anti-sintering.ʻO ka maʻamau, hoʻohana ʻia ka ʻaila stamping e loaʻa ana i ka sulfur a me ka chlorine compound additives e hōʻoia i ka hana ikaika loa a pale aku i ka burr, crack a me nā pilikia ʻē aʻe o ka mea hana.

ʻO kēia nā mea e pili ana i ka maikaʻi o nā ʻāpana stamping metala.Me ka hoʻomohala wikiwiki ʻana o ka ʻenehana stamping precision, hiki i nā ʻāpana stamping liʻiliʻi ke hoʻokō i nā pono o nā ʻano mea hana mīkini, nā mea uila, nā mea hana a me nā ʻoihana hana ʻē aʻe.He kahua noiʻi a hoʻomohala ʻo MINGXING no nā mea hana metala kiʻekiʻe.ʻO ka ʻaila stamping kūʻokoʻa i hoʻomohala ʻia he koʻikoʻi koʻikoʻi a me ka hana anti-wear, hiki ke pale pono i ka make, hoʻomaikaʻi nui i ka pono, a hoʻonui i ke ola lawelawe o nā mea hana.ʻO ia ka hoa i koho ʻia o nā ʻoihana mīkini mīkini nui a me ka nui ma Kina, a ua lanakila ʻo ia i ka ʻike ākea a me ka mahalo kiʻekiʻe ma ka ʻoihana.

Ka manawa hoʻouna: Feb-16-2023