-

Several Common Stamping Processes for Metal Stamping Parts

At present, it can be said that sheet metal stamping is a kind of processing method with high production efficiency, low material loss and low processing costs. With the advantage of high precision, stamping is suitable for the production for large quantities of hardware...Read more -

How does the stamping factory inspect the metal stamping parts?

1. Touch test Wipe the surface of the outer covering with clean gauze. The inspector needs to wear touch gloves and touch along the longitudinal direction of the stamping parts close to the surface of the stamping parts. This inspe...Read more -

Influence of Blanking Clearance on Dimension Precision of Blanking Parts

The dimensional accuracy of blanking parts refers to the difference between the actual size of blanking parts and the basic size on the drawing. The smaller the difference, the higher the accuracy. This difference includes two deviations: one is the deviation of the blan...Read more -

Professional Manufacturer for Custom Aluminum Extrusion Profile

Aluminium profiles can be found everywhere in our production industries and daily life. In the field of industrial production and manufacturing, it’s called industrial aluminium profiles. In addition, there still have the aluminum profile applied to construction. Here we...Read more -

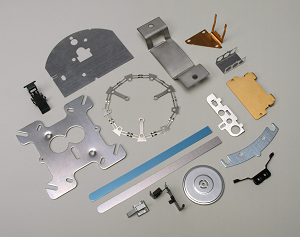

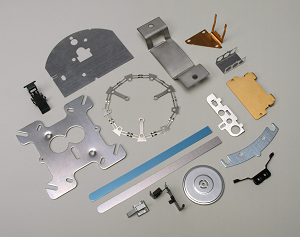

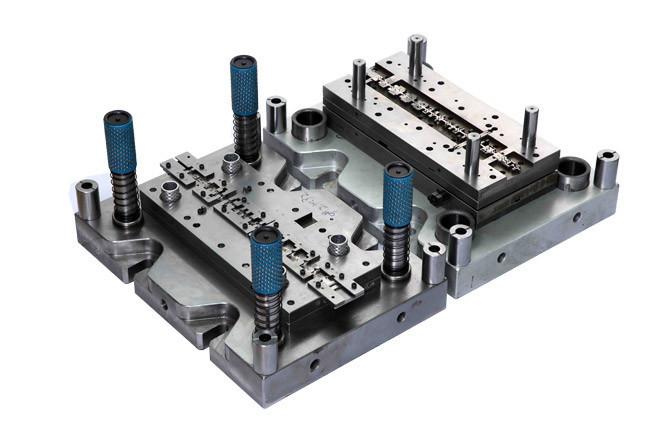

A Brief Introdution of Metal Stamped Parts

1. Stamped parts are made by applying external forces to sheets, plates, strips, tubes and profiles by means of a press and a die to produce a plastic deformation or separation to obtain a workpiece of the required shape and size. 2. Stamped parts are mainly made of meta...Read more -

Main Factors Affecting the Continuous Stability of Metal Stamping Parts

Because most of the domestic mold manufacturing enterprises are small and medium-sized enterprises, and quite a few of these enterprises are still in the traditional workshop production management stage, often ignoring the stability of the mold, resulting in long mold de...Read more -

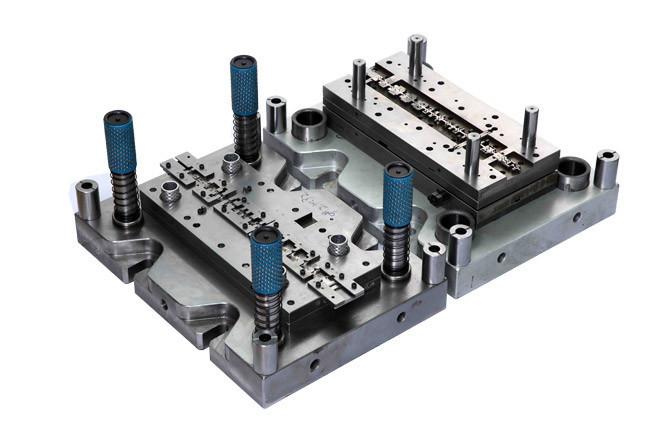

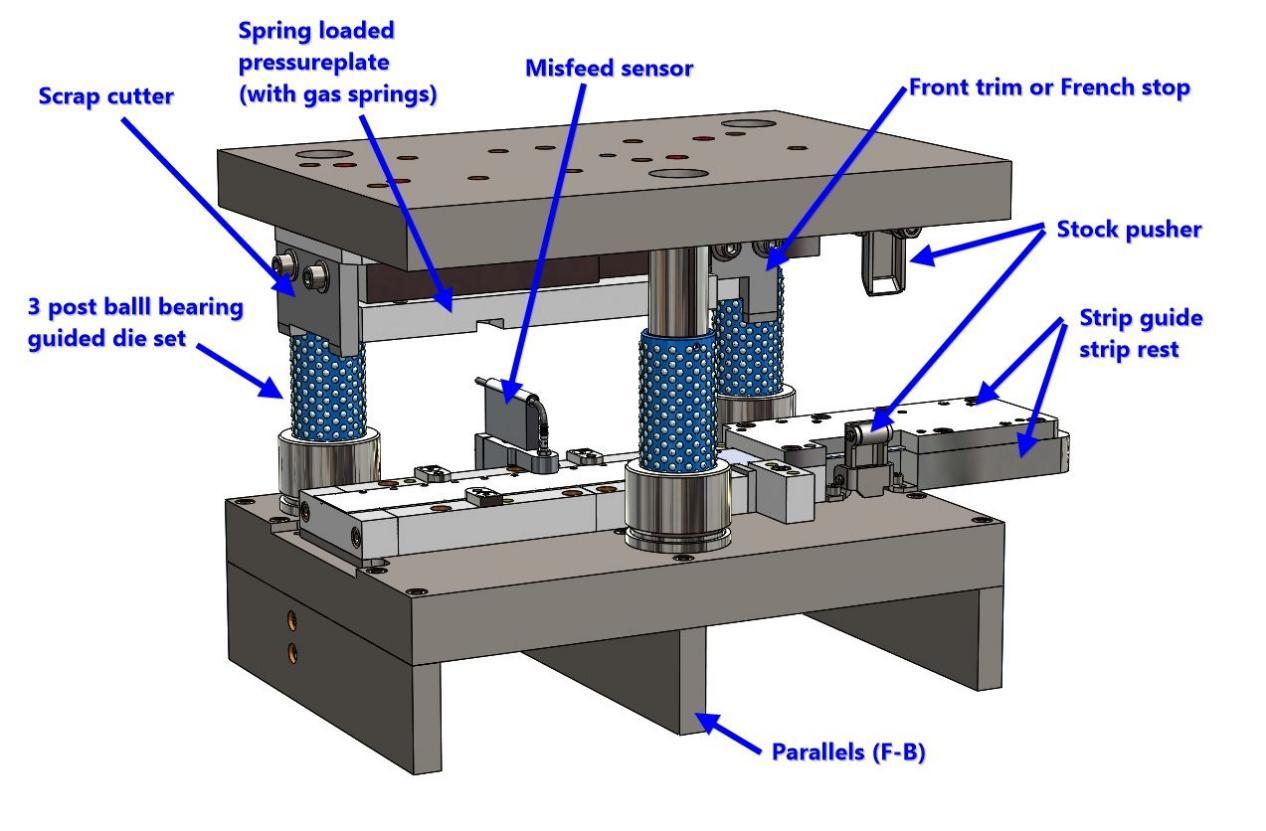

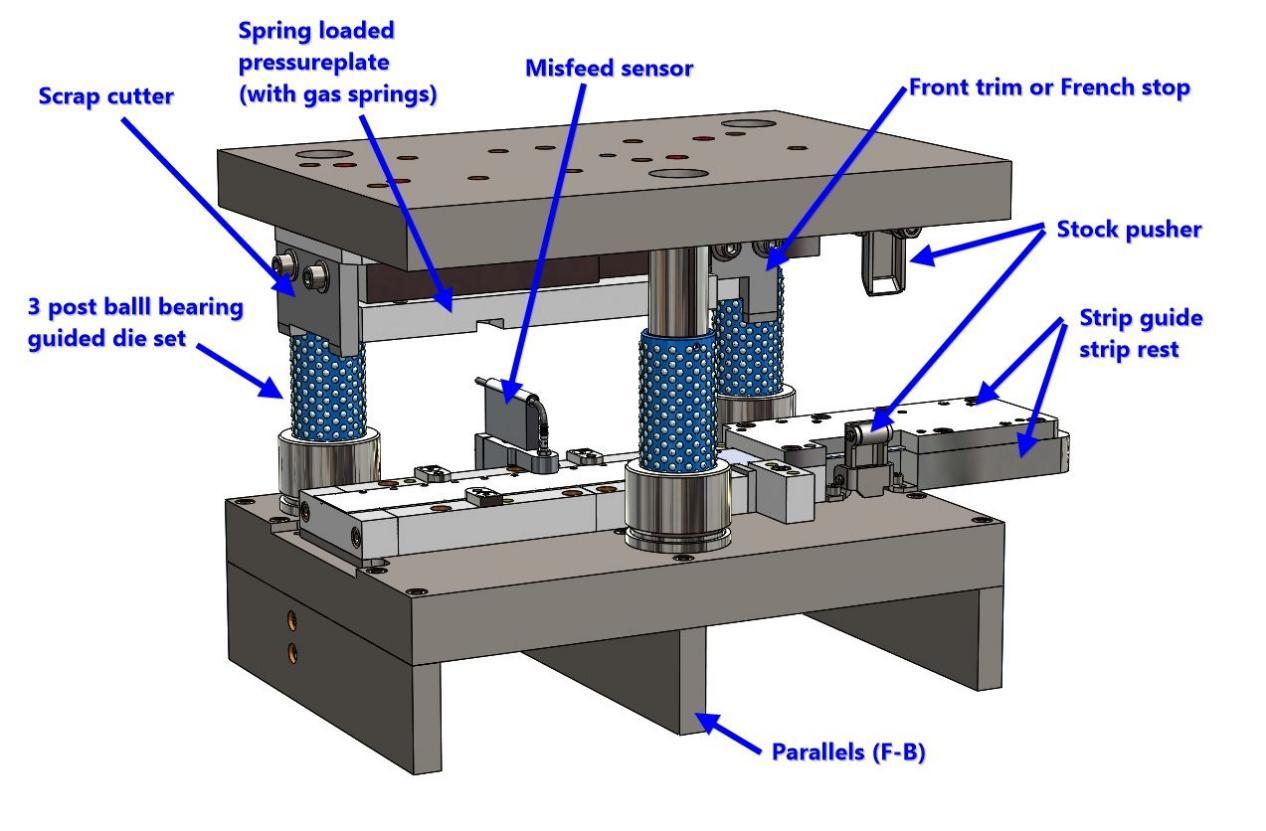

Common terms of metal stamping dies

1. Blanking Blanking is a kind of stamping process in which part of materials or process parts are separated from another part of materials, process parts or waste materials by using stamping dies. Blanking is a general term for such separation processes as cutting, blan...Read more -

Advantages of Anodizing for Extruded Aluminium Alloy Parts

Anodizing is one of the most durable forms of surface treatment. This full process improves the shape and working of CNC machined parts. It also facilitates the bonding between top coat and strong adhesive in aluminium die-cast and extruded aluminium components. ...Read more -

Common Materials Used for Stamping Metal Connectors

OEM automotive wiring connectors mainly include hardware shrapnel, terminals, rivets, bolts, high strength bolts, welding rods, pivots (pins), etc. Commonly used materials are: copper, brass, tin-phosphor bronze, beryllium bronze, copper alloy, steel, gold, nickel, etc. ...Read more -

Positive Adjustment for Layout of Domestic Hardware Stamping Die Industry

At present, the domestic precise stamping die is heading for international level positively by participating in international competition. Since establishment, China’s stamping die industry has been developed quickly, occupying 40.33% and 25.12% of total import and expor...Read more -

China’s hardware stamping dies are catching up with the world’s advanced level.

As one of the industries developing quickly at domestic die production field, the technology-intensive hardware stamping dies have been developed towards high-end, large-scale, precise and compound tendency and become the important power for driving China to grow up to a...Read more -

Manufacture Industry: Analysis for Hardware Stamping Industry

The hardware stamping refers to the processing method for gaining the required shape and dimension work pieces by exerting external force on materials, such as plate and belt with punch and stamping dies and then making plastic deformation or separation. In consideration...Read more