1. Blanking

Blanking is a kind of stamping process in which part of materials or process parts are separated from another part of materials, process parts or waste materials by using stamping dies. Blanking is a general term for such separation processes as cutting, blanking, punching, punching, notching, sectioning, chiseling, edge cutting, tongue cutting, cutting, trimming, etc.

2. Incision

Cutting is a stamping process that separates materials locally along the open contour rather than completely. The material that is cut and separated is located or basically located in the plane before separation.

3. Trimming

Trimming is a stamping process that uses a die to trim and shape the edge of a working part to make it have a certain diameter, height or shape.

4. Enucleation

Tongue cutting is a stamping process that separates materials locally along the open contour rather than completely. The partially separated material has a certain position required by the workpiece and is no longer on the plane before separation. cut off

5. Cut off

Cutting is a stamping process that separates materials along the open contour. The separated materials become workpieces or process pieces.

6. Flaring

Flaring is a stamping process to expand the open part of hollow parts or tubular parts outward.

7. Punching

Punching is a kind of stamping process that separates waste materials from materials or process pieces along the closed contour to obtain the required holes on materials or process pieces.

8. Washout

Punching is a stamping process that separates waste materials from materials or process parts along the open contour. The open contour forms a gap whose depth does not exceed the width.

9. Flume

Punching groove is a stamping process that separates waste materials from materials or process parts along the open contour. The open contour is shaped like a groove, and its depth exceeds the width.

10. Punching center hole

Punching the center hole is a stamping process that forms a shallow concave center hole on the surface of the process part, and there is no corresponding bulge on the back material.

11. Fine blanking

Fine blanking is a kind of smooth blanking. It uses a fine blanking die with a toothed pressing plate to make the entire section of the stamping part completely or basically smooth.

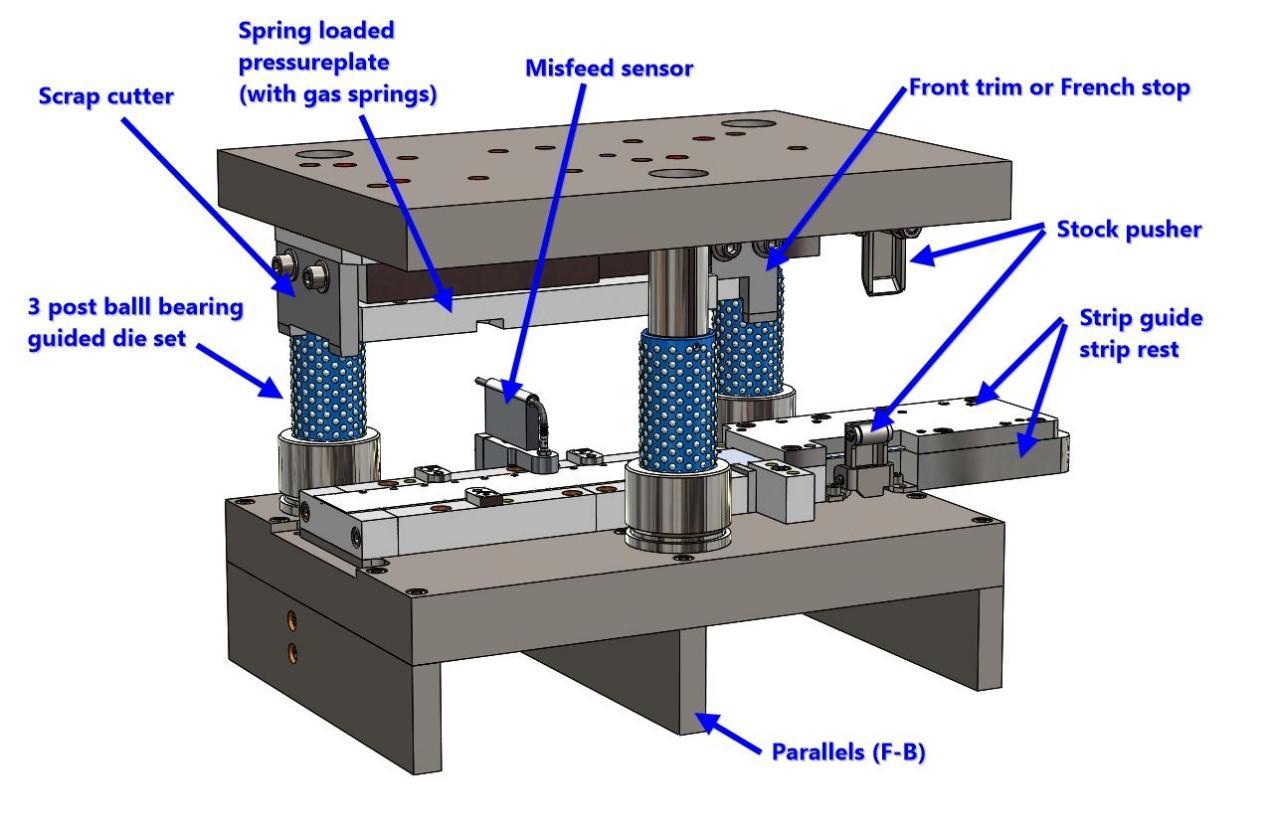

12. Continuous mode

The continuous die is a die with two or more stations. The materials are sent to one station one by one with the stroke of the press, so that the stamping parts are gradually formed.

13. Single process die

Single process die is a die that only completes one process in one stroke of the press.

14. Combined die

The combined die is a universal and adjustable complete set of die for various stamping parts, which is formed according to the geometric elements (straight line, angle, arc, hole) one by one. The contour of a plane shaped stamping part generally requires several sets of combined stamping dies to be punched in several times.

15. Embossment

Convex pressing is a kind of stamping process in which a punch is squeezed into one side of the process part to force the material into the opposite pit to form a bulge.

16. Embossing

Embossing is a stamping process that forcibly extrudes materials locally and forms shallow concave patterns, patterns, characters or symbols on the surface of process parts. The back surface of the embossed surface has no convex corresponding to the shallow concave.

Post time: Oct-22-2022