-

Several common methods of aluminum surface treatment in precision hardware processing

In precision hardware processing, aluminum is often subjected to various surface treatment methods to enhance its appearance, durability, and functionality. Here are several common methods of aluminum surface treatment: 1. Anodizing: - Description: Anodizing is an electrochemical proce...Read more -

The stamping manufacturing process offers several advantages for producing hardware parts

1. Cost-Effective Production: Stamping is a highly efficient and cost-effective method for mass production of hardware parts. The process allows for the quick and precise creation of identical components, reducing production costs. 2. High Precision and Accuracy: Stamping allows for the productio...Read more -

Stability of Metal Stamping Production and Its Influence Factors

What is stability? Stability is divided into process stability and production stability. Process stability refers to meet the production of qualified products with stability of the process program; production stability refers to the production process with stability of production capacity. As th...Read more -

Factors Affecting the Durability of Stamping Die

The durability of a stamping die, the workhorse of sheet metal shaping, is crucial for consistent production and cost-effectiveness. Here are some key factors that impact its lifespan: Material and Design: Die Material: Choosing the right tool steel for the job is critical. Factors like wear resi...Read more -

What factors affect the service life of metal stamping products?

The service life of metal stamping products, meaning how long they last before needing replacement, is influenced by several factors, which can be grouped into three main categories: 1. Material and Design: Material Properties: The type of metal used plays a crucial role. Softer metals wear out f...Read more -

Definition and Development Status of Hardware Stamping Technology

1. Definition of Metal Stamping Technology Hardware stamping processing technology refers to the use of stamping equipment and molds, through a series of punching, stretching, bending and other deformation processes of sheet metal, processing it into parts of the required shape and size. It is an...Read more -

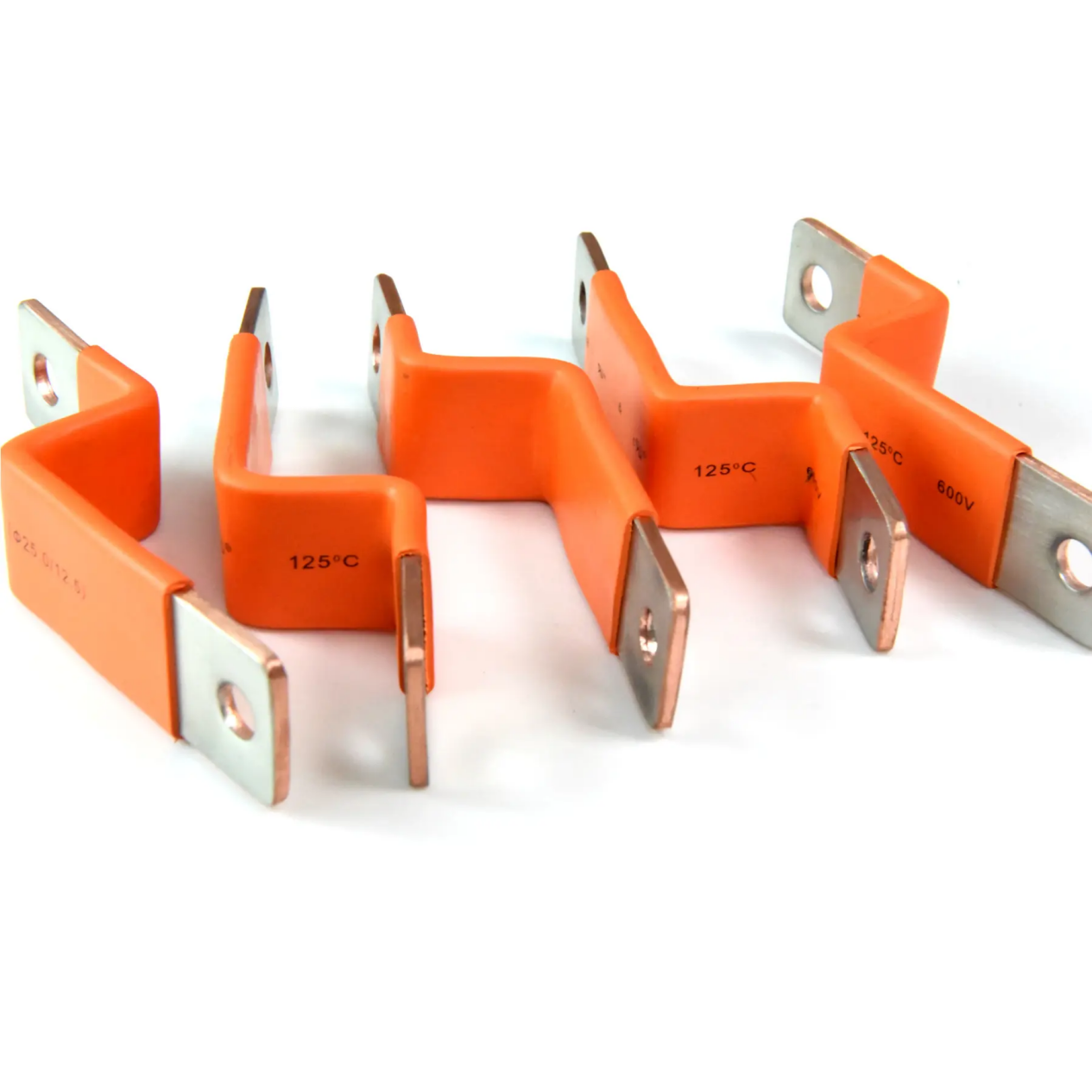

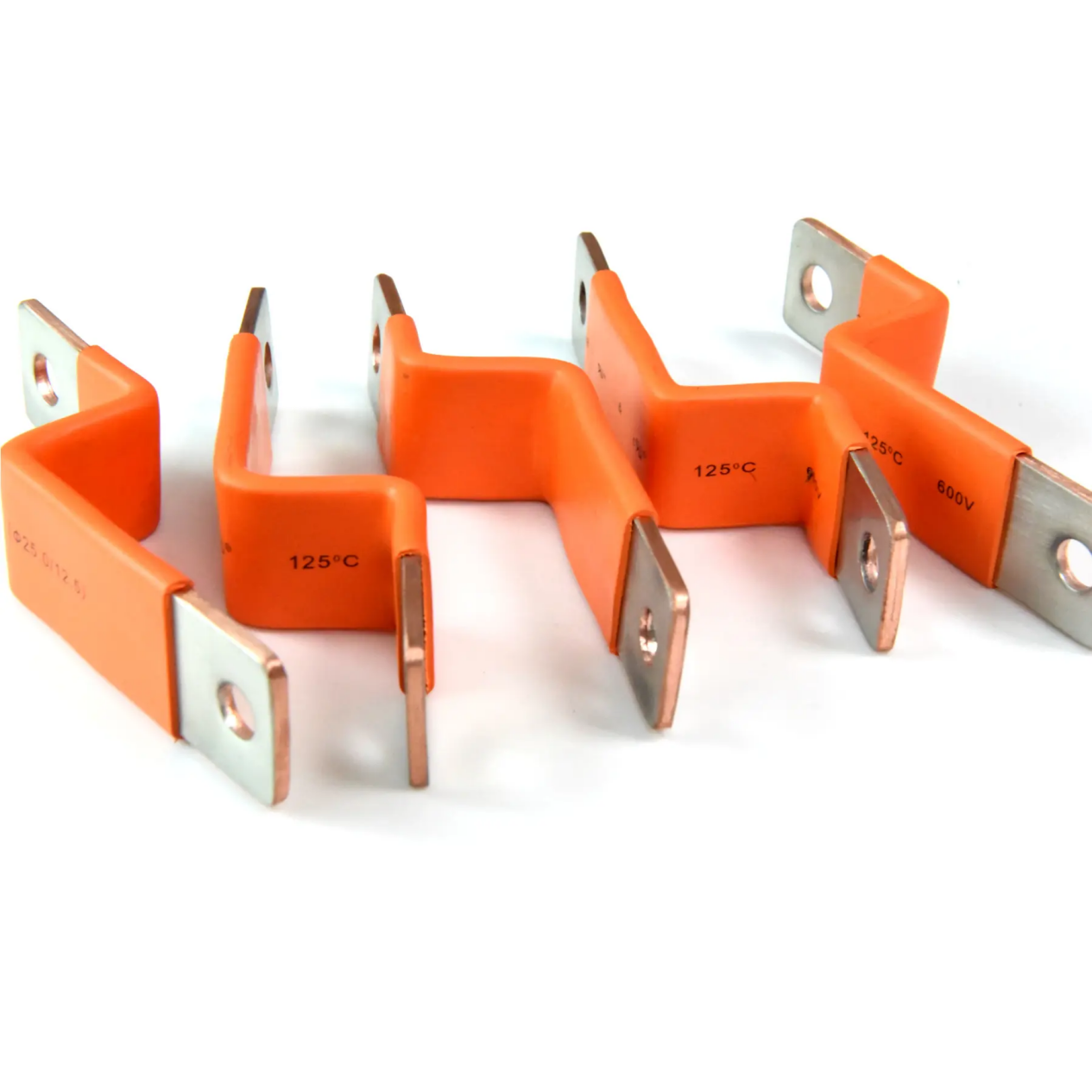

Flexible copper busbars offer several advantages

Flexible copper busbars offer several advantages, including: 1. Excellent Conductivity: Copper, known for its superior conductivity, ensures efficient current transmission, reducing resistance and enhancing energy transfer efficiency. 2. High Flexibility and Malleability: These busbars exhibit hi...Read more -

Flexible copper busbars find application in various fields

Flexible copper busbars find application in various fields, including but not limited to: 1. Power Systems: Used to connect generators, transformers, and distribution equipment in power systems, facilitating current transmission and efficient power distribution. 2. Renewable Energy: Employed in r...Read more -

The Difference between Hard and Soft Copper Busbars for New Energy Vehicles

Nowadays more and more new energy vehicles are put into the market for sale and use. Unlike conventional fuel vehicles in the past, the voltage and current values of new energy vehicles (power electronics, strong electricity) are much higher than those of conventional fuel vehicle electrical syst...Read more -

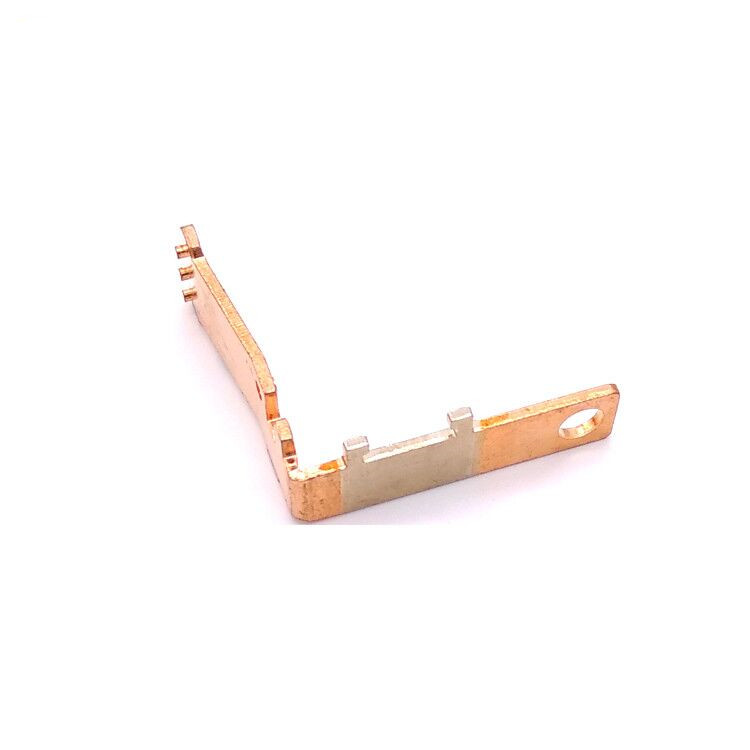

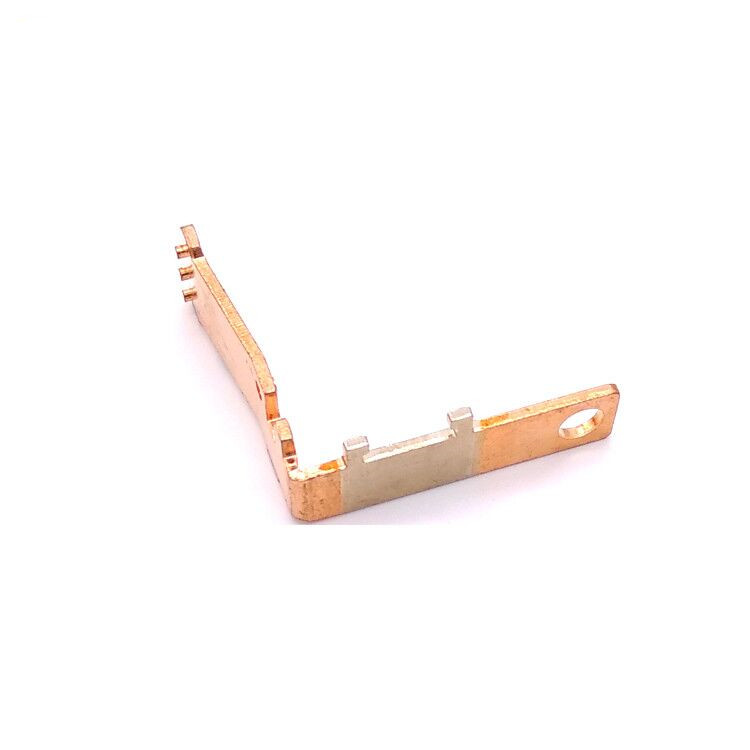

What is a flexible copper busbar?

A flexible copper busbar is a conductive component made of copper, typically in a flat shape, possessing high flexibility and malleability. It is commonly utilized for electrical connections and conduction in power systems, electronic devices, and various applications including new energy vehicle...Read more -

The reason for using flexible copper busbars to connect battery modules in new energy vehicles?

The main reasons for using flexible copper busbars to connect battery modules in new energy vehicles are: 1. Superior Conductivity: Flexible copper busbars possess excellent conductivity, efficiently transmitting current, reducing resistance, and ensuring the efficient transfer of electrical ener...Read more -

Six Common Hardware Stamping Methods

Hardware stamping involves a variety of different processes depending on the shape of the part or product. These processes are used to realize complex and detailed designs for parts and products in industries that include aerospace, consumer products, automotive, aviation, electronics and more. I...Read more