1. Cost-Effective Production: Stamping is a highly efficient and cost-effective method for mass production of hardware parts. The process allows for the quick and precise creation of identical components, reducing production costs.

2. High Precision and Accuracy: Stamping allows for the production of highly precise and accurate parts. The use of dies ensures consistency in dimensions and shapes, resulting in parts that meet tight tolerances.

3. Speed of Production: Stamping is a fast manufacturing process, making it suitable for high-volume production. The rapid and automated nature of stamping operations contributes to increased production speed.

4. Material Utilization: Stamping optimizes material utilization, minimizing waste. The process involves cutting or forming parts from sheet metal, leading to efficient use of raw materials and reduced scrap.

5. Versatility: Stamping is a versatile process that can be used for a wide range of materials, including metals and alloys. It can accommodate different thicknesses and types of materials, providing flexibility in design and material selection.

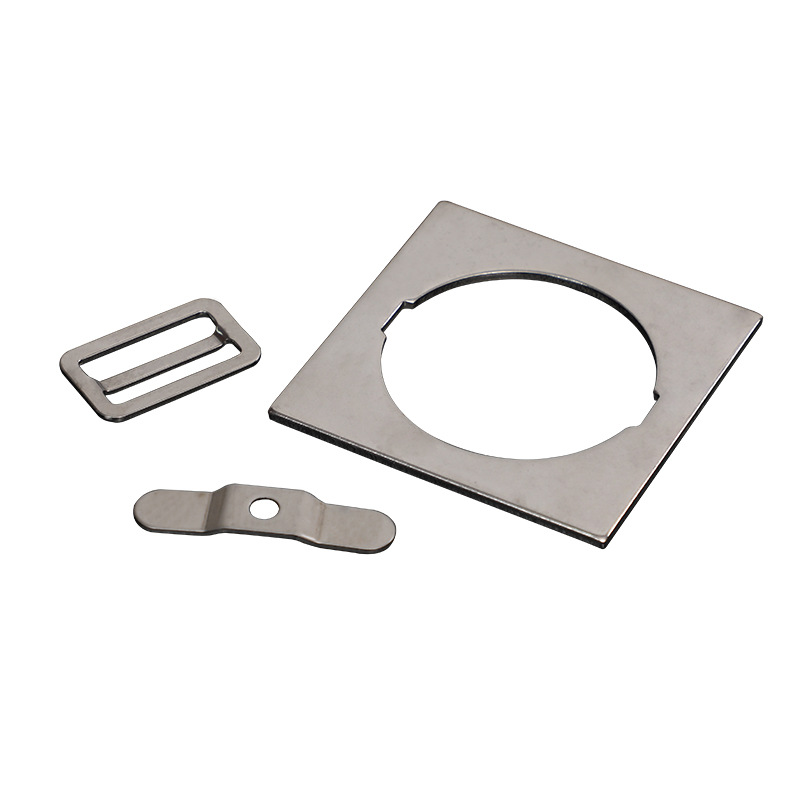

6. Complex Shapes and Features: The stamping process enables the creation of complex shapes and features in hardware parts. This is achieved through the use of multi-step dies and tooling, allowing for intricate designs.

7. High Production Rates: The combination of automation and speed in stamping results in high production rates. This is particularly advantageous for industries that require large quantities of hardware parts within short timeframes.

8. Consistency in Quality: Stamping ensures consistent quality across a large batch of parts. The use of dies and automated machinery minimizes variations, leading to uniformity in the produced components.

9. Reduced Labor Costs: Automation in stamping processes reduces the reliance on manual labor, leading to lower labor costs. This is especially beneficial for companies seeking cost-effective solutions for high-volume production.

10. Tooling Longevity: Well-maintained dies and tooling used in stamping can have a long lifespan, contributing to sustained production efficiency over time.

In summary, the stamping manufacturing process offers cost-effective, high-speed, and high-precision production capabilities, making it a preferred method for manufacturing hardware parts, particularly in industries with a focus on mass production.

Post time: Jan-17-2024