-

How to Choose Mold Steel and Processing Methods for Stamping Die

Hardware stamping die uses various metal and non-metal materials, which are mainly carbon steel, alloy steel, cast iron, cast steel, hard alloy, low melting point alloy, zinc-based alloy, aluminum bronze, etc. The material for manufacturing hardware stamping dies requires high hardness, high stre...Read more -

Reasons and Solutions for Chip Jumping of Die Scrap in Hardware Stamping Process

The so-called scrap jumping refers to that the scrap goes up to the die surface during the stamping process. If you do not pay attention in the stamping production, the upward scrap may crush the product, reduce the production efficiency, and even damage the mold. Reasons for scrap jumping includ...Read more -

Problems and Solutions of Punching and Flanging in Hardware Stamping

When punching and flanging in metal stamping, the deformation area is basically limited within the fillet of the die. Under the action of unidirectional or bidirectional tensile stress, the tangential elongation deformation is greater than the radial compression deformation, resulting in material...Read more -

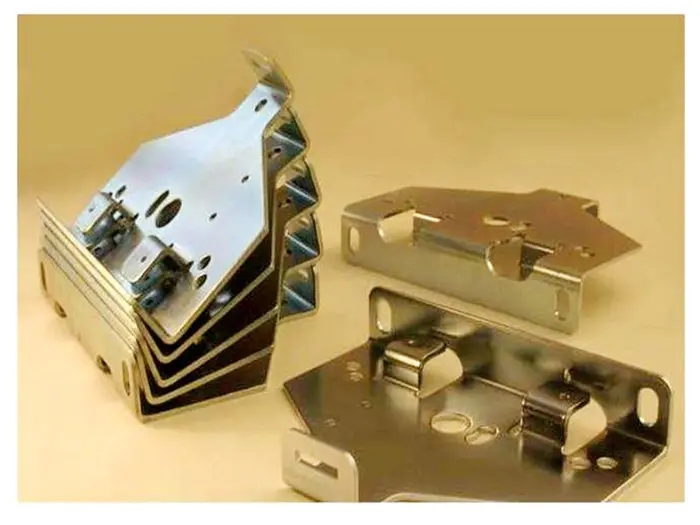

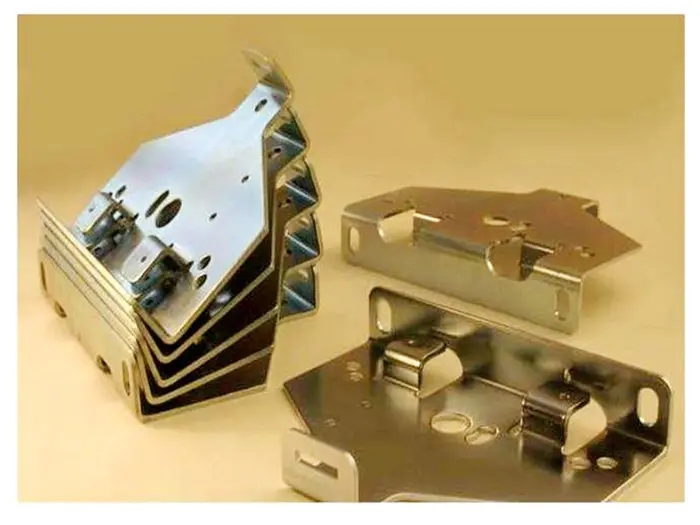

Custom Metal Stamping Products for Every Industry

Metal stamping is a manufacturing process in which sheet metal is converted into different shapes with the help of dies and stamping machines. It involves several processes to form the metal into the desired shape. Metal stamping is a low cost and fast manufacturing process that can produce large...Read more -

How to Make the Best Choice Between Hardware Stamping and Laser Cutting?

Hardware stamping and laser cutting are relatively different processes, but can achieve the same result. Hardware stamping is a hardware process that uses a stamping press to process, which requires the use of a die to shape or mold the part you want. In hardware stamping, the die is forced into ...Read more -

What are the characteristics of metal stamping parts?

Stamping parts are mainly formed by stamping metal or non-metallic sheets with the help of the pressure of the press and through the stamping die. They mainly have the following characteristics: ⑴ Stamping parts are manufactured by stamping under the premise of small material consumption. The par...Read more -

Introduction to Raw Materials of Common Metal Stamping Parts in Stamping Factory

The performance requirements of raw materials for metal stamping parts involve the physical properties such as material hardness, material tensile strength, and material shear strength. The stamping forming process involves stamping cutting, stamping bending, stamping stretching and other related...Read more -

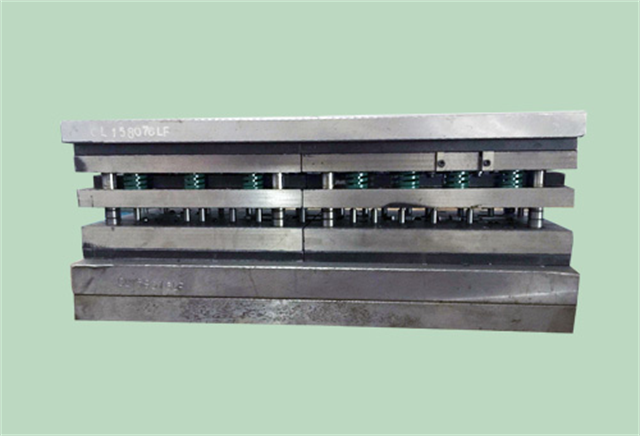

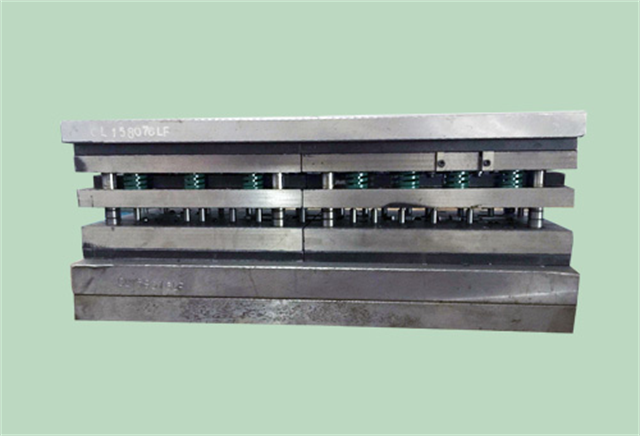

Types of Metal Stamping Dies

Hardware stamping die, a special process equipment for processing materials (metal or non-metal) into parts (or semi-finished products) in cold stamping process, is called cold stamping die (commonly known as cold punching die). Stamping, is a pressure processing method that uses a die mounted on...Read more -

The Relationship Between Sheet Metal Processing and Stamping Processing

For those who first encounter sheet metal processing, most people are easily confused with the concept of sheet metal processing and stamping. In most of the sheet metal processing, the stamping process is indispensable. It can be said that there is an inseparable connection between sheet metal p...Read more -

How to Improve the Processing Efficiency of Stamping Parts and How to Solve the Wrinkle Problem of Stamping Parts

For hardware stamping parts manufacturers, the processing efficiency of stamping parts is directly related to the profits, and stamping parts are required in many fields, such as ordinary automobile stamping parts, auto parts stamping parts, electrical accessories stamping parts, daily stamping p...Read more -

Key Points of Design Principles for Hardware Stamping Parts

With the continuous improvement of the wage level of workers in the stamping industry, reducing the manual manufacturing cost of stamping has become an urgent task for hardware stamping parts processing manufacturers. One of them is the use of continuous die, which can be used to establish a low-...Read more -

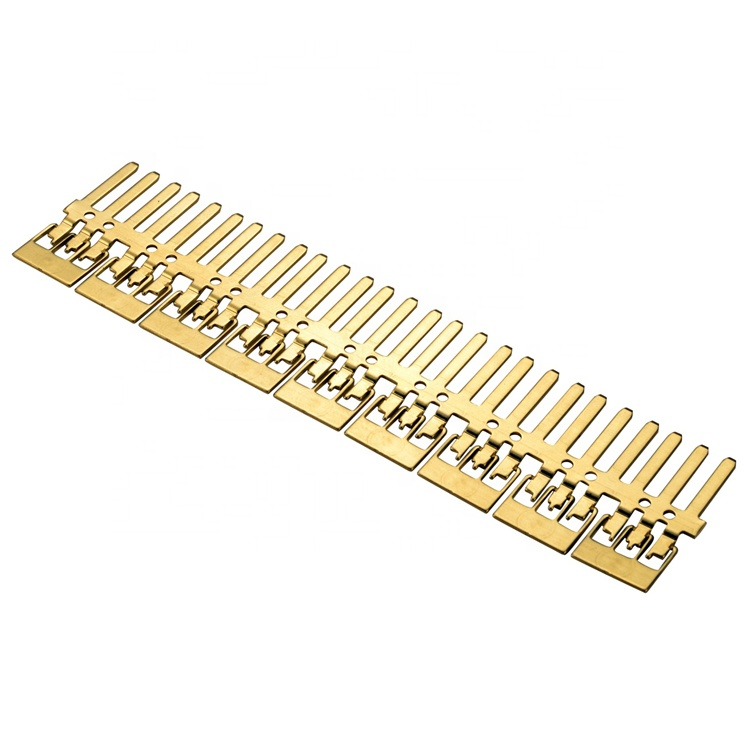

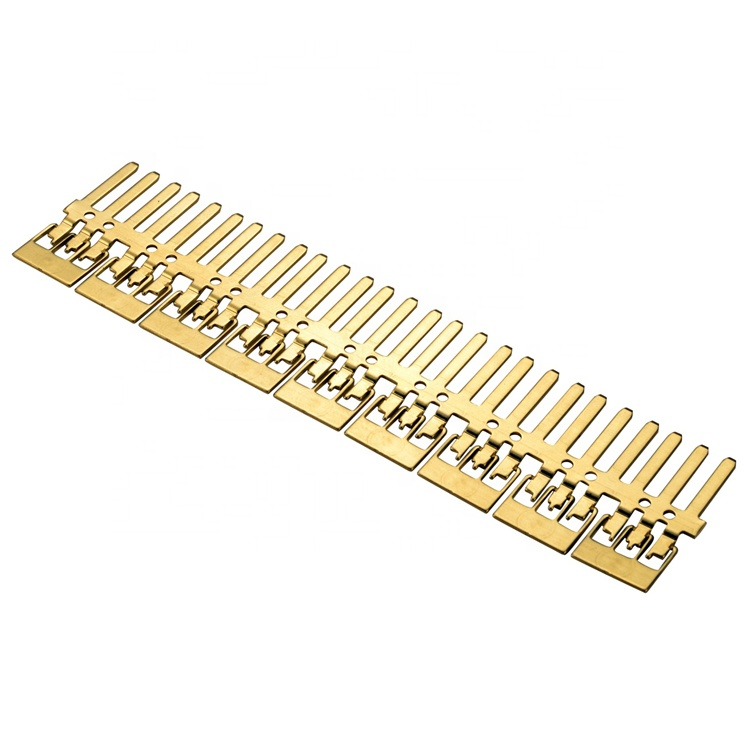

How to Choose Matte Tin or Bright Tin Plating for Connector Pins?

How to choose between matte tin and bright tin for connector pins? As a pin research and development manufacturer, the surface treatment of pin is very important, because this is the last vital process of product forming. So how to choose matte tin and bright tin plating...Read more