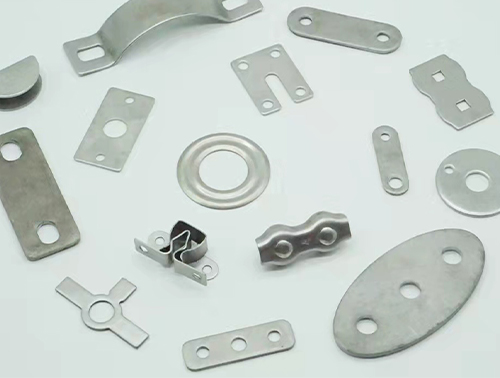

Stamping process is a production technology to obtain product parts of certain shape, size and performance by deforming the sheet material directly in the die with the power of conventional or special stamping equipment, and stamping process can be divided into precision stamping and general stamping.

Precision stamping is a material processing method developed on the basis of common stamping process. It is a process to obtain precision stamped parts by improving the guiding accuracy, reducing the gap between the convex and concave dies, increasing the reverse pressure and the V-ring crimping circle, etc., resulting in the process of precision stamping or precision stamping compounded with other forming processes under the condition of strong three-way compressive stress.

Precision metal stamping requires high precision of stamped parts. In the process of processing and production, stamping rolls or forming, the technical support of suitable precision presses, dies, materials, lubricants, etc. must be considered, and the requirements are high. Ordinary stamping requires less precision for stamped parts, but it also has its specific market demand. The thickness of the base material is thicker and does not require cutting, chipping, stretching and other processes, and the stamping materials are plates, pipes, etc. When the single quantity of the product is not required, ordinary stamping can meet the requirements. In the production process of precision stamping parts processing, stamping coils or forming, it is necessary to consider the technical support of suitable precision punching machines, dies, materials, lubricants, etc.

The other one applies about 25% of the main blanking pressure at the end of the product’s rewinders, which is called the counter pressure. These three presses do not interfere with each other, and the magnitude of each pressure is synchronized with the forming, and must be suitable for the processing requirements of forming and blanking, etc., and can be adjusted at will. In addition, the processing speed must also be adjusted according to the requirements of the forming or blanking processing object conditions. The structure of the die is not only simple and light weight, but also suitable for use.

The difference between precision stamping and ordinary stamping lies in the requirements for stamping equipment and the precision of the required stamped parts. On the contrary, if the requirements for the precision of the stamping parts are not too high and the stamping is done by common sheet material, the common stamping machine can be selected according to the stamping characteristics.

Post time: Jan-10-2023