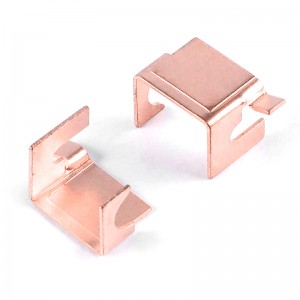

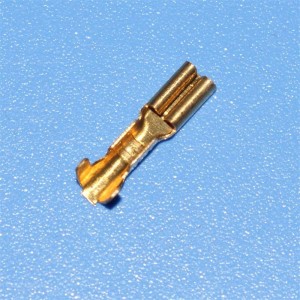

Product Description

| Item name | OEM Metal Stamping Brass Terminal Pin Connector for Socket |

| Material | Copper Alloy, Brass, Phosphor Copper, Aluminum Alloy, Stainless Steel, etc. |

| Mold Type | Progressive tool |

| Surface Treatment | Plating, Anodized, Polished, Powder Coated, Painting, etc. |

| Tolerance | as per customers' requirement |

| Quality Assurance | 100% CCD inspection and QC spot check per 2 hours. |

| Process | Stamping, machining, bending, deep drawing, welding, riveting |

| Our Production Cycles | 21 working days for the new mold and within 7 working days for exiting model(Depends on the QTY) |

Custom Stamping Terminal Capabilities

Mingxing is IATF-certified and ISO 9001-certified, you can be assured for the safety and quality of the stamped products we produce. We design various metal stamped parts strictly as customer’s requirement by CAD and inspected by 24h salt spray test and projector. The manufacturing processes we can be used include stamping, bending, laser cutting, blanking, drilling, lathe and mill, etc.

Our Advantages

1. Professional Stamping Manufacturer: All of our products are designed and manufactured according to buyer's specification and performance.

2. Quality is guaranteed: Durability testing and critical technical design to enhance metal stamped parts lifetime.

3. Coslt effective: Competitive prices with professional factory supply.

Q. Are you a factory or a trade company?

A:We're a factory with over 20 years experience in the heat sink field.It is a enterprise that professionally design and produce Heat sinks, electronic components, auto parts and other stamping products.

Q. How to get a quotation?

A: Please send us info such as drawing,material surface finish,quantity.

Q. What about the lead time?

A: Average for 12 working days, open mould for 7 days and mass production for 10 days

Q. Do the products of all the colors are the same with same surface treatment?

A: No. about powder coating, the bright-color will higher than white or gray. About the Anodizing, colorful will higher than silver, and black higher than colorful.

-

OEM Stamped Parts Copper Switch Contact Connect...

-

OEM Stainless Steel Contact Terminal Stamping P...

-

Automotive Connector Cable Wire Terminal Brass ...

-

Custom Metal Stamping Connection Terminal Spare...

-

OEM Service Precision Stamping Copper Connector...

-

China OEM Stamped Parts Copper Brass Electrical...