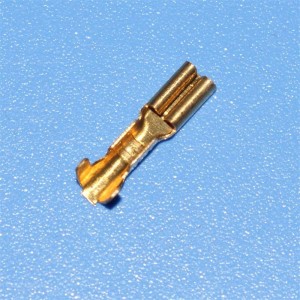

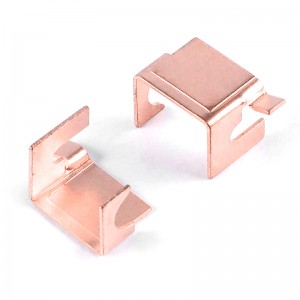

Product Description

| Item name | Automotive Connector Cable Wire Terminal Brass Crimp Terminal |

| Material | Brass, Copper, Phosphor copper, Copper Alloy, Stainless Steel, etc. |

| Mold Type | Progressive tool |

| Surface Treatment | Nickel or Tin plating, Insulated, Powder Coated, Painting, etc. |

| Tolerance | as per customers' requirement |

| Quality Assurance | 100% CCD inspection and QC spot check per 2 hours. |

| Process | Stamping, machining, bending, deep drawing, welding, riveting |

| Mass production | 21 working days for the new mold and within 7 working days for exiting model after receipt of deposit. (Depends on the QTY) |

Custom Stamping Terminal Capabilities

A stamped terminal is a component commonly used for electrical connections, usually to hold wires or conductors and connect them to a circuit board or device. The manufacturing process is done by stamping a metal sheet into a specific shape and then using a machine to insert the wire inside the terminal to form a stable and reliable electrical connection. This type of connection is widely used in various devices and industries, such as home appliances, automotive, aerospace, medical, etc.

Q1: Are you a direct manufacturer?

A:Yes,we are direct manufacturer.We have been in this domain since 2006. And if you want, we could chatting with you on video via Wechat/Whatsapp and any way you like to show you our plant.

Q2: How can you guarantee quality?

A: Always a pre-production sample before mass production;

Always 100% inspection before shipment;

Q3: What kind of service/products you provide?

A: Service of OEM/ one-stop service/ assembly; From mold design, mold making, machining, fabrication, welding, surface, treatment, assembly, packing to shipping.

-

Custom Metal Stamping Connection Terminal Spare...

-

OEM Metal Stamping Brass Terminal Pin Connector...

-

China OEM Stamped Parts Copper Brass Electrical...

-

OEM Service Precision Stamping Copper Connector...

-

OEM Stamped Parts Copper Switch Contact Connect...

-

OEM Stainless Steel Contact Terminal Stamping P...