Jewerly is always popular with a lot of people, and now both men and women or young and old have jewelry for themselves. Although jewelry looks exquisite and beautiful, but the finished jewelry is produced by people’s many layers of processes, which uses many different production processes. Since some people are also interested in the production process of jewelry, compared to the traditional metal stampings, so what is the metal jewelry stamping?

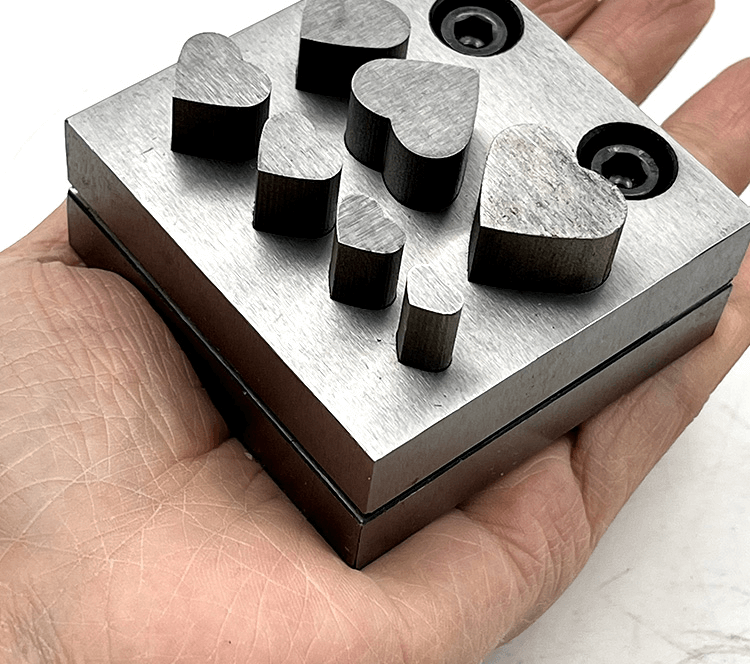

1.The stamping process of jewelry, also known as die stamping press and embossing, is a relief pattern manufacturing process. The processes of the jewelry stamping are mainly to make a mold according to a master mold and then to create a relief pattern on the metal by pressure. The process of stamping jewelry mainly involves embossing the pattern, then forming it, and finally, usually using solder to combine the companies so that a finished piece of jewelry is made.

2.The stamping process of jewelry is mainly applicable to jewelry with concave and convex bottom surface, such as the small lock pieces we commonly see, or jewelry with inconspicuous undulations that can be easily formed or combined in two or more stamping steps, in addition to the thinner jewelry parts and jewelry requiring delicate and exquisite patterns also need to be processed with the stamping process.

3.Compared with the lost wax (investment mold) casting jewelry parts, the stamping parts have the characteristics of thin, uniform, light and strong, and the use of stamping method can greatly reduce the wall thickness of the workpiece, so as to reduce the weight of jewelry parts and improve the economic efficiency. The jewelry parts produced by mechanical stamping method have less holes and good surface quality, which improves the quality and yield of jewelry products and reduces the scrap rate. In mass production, the stamping process has high production efficiency, good labor conditions and low production cost. When the precision of the mold is high, the precision of the stamped jewelry pieces is high, and the repeatability is good and the specifications are consistent, which greatly reduces the workload of trimming, grinding and polishing. The stamping process can achieve a high degree of mechanization and automation.

Post time: Mar-10-2023