A power battery system refers to energy storage devices used to supply energy to the drive of an electric vehicle and consists of one or more battery packs and a bms control system. The reliability and longevity of the power battery pack, the core of a pure electric vehicle, is the key to the range of the nickel strip. The material of one of the power cell connecting tabs is one of the key factors affecting the performance of the battery pack. The power battery module is assembled by several single cells in series and parallel, and the connection and fastening between the single cells requires a small contact resistance, vibration resistance and high reliability between the connection piece and the battery pole. So how to choose the bms battery connector material to ensure that the battery performance is greater?

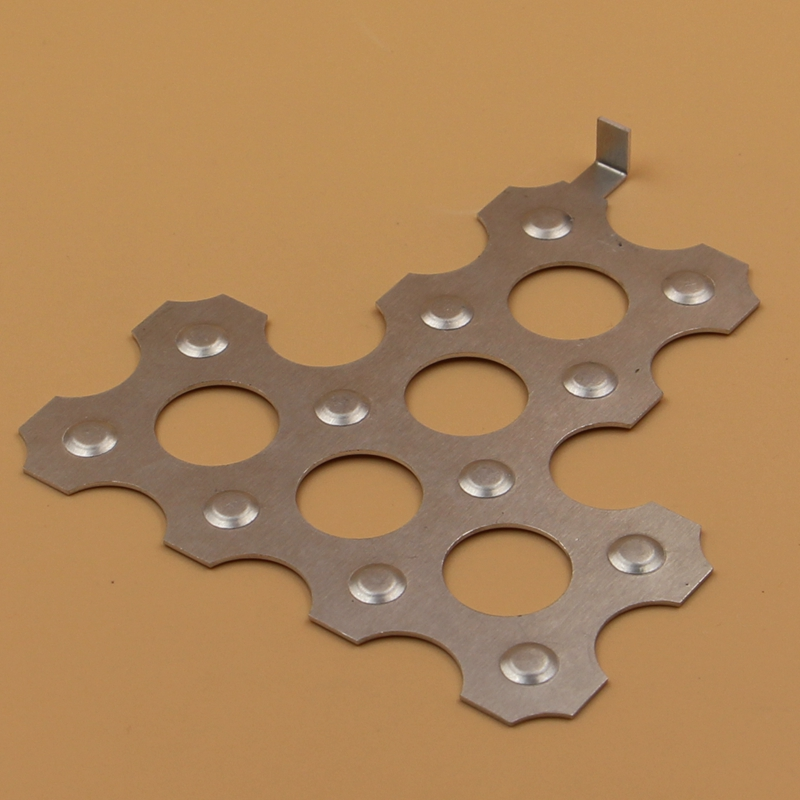

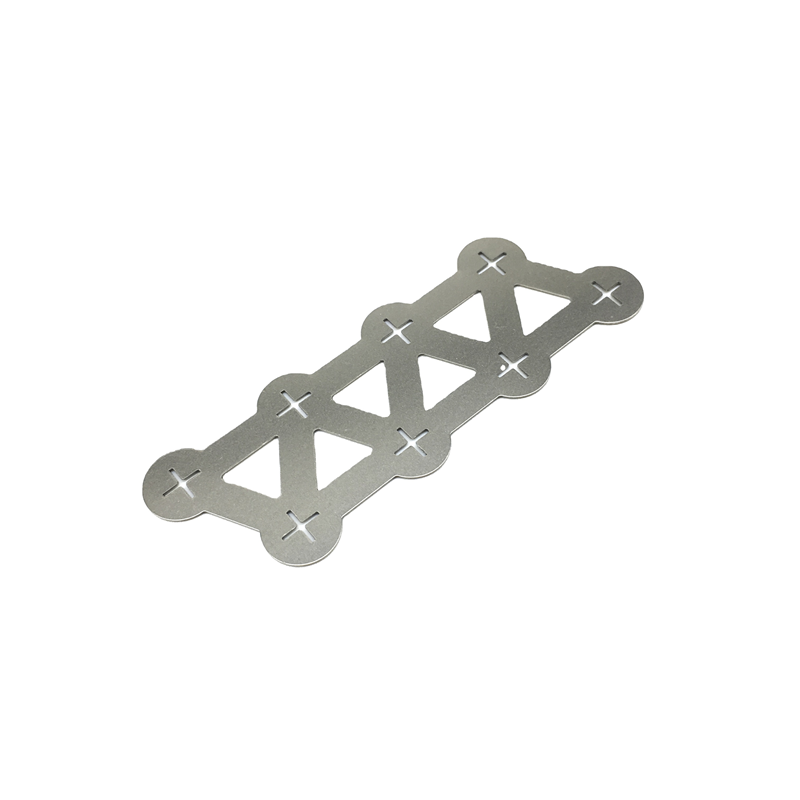

Battery connectors are generally trapezoidal, rectangular, triangular and phase-shaped. Whether by laser welding, resistance welding or bolt mechanical locking, it is necessary to ensure the reliability and durability of the battery system in the actual driving process of electric vehicles, nickel-plated steel belt a relatively high nickel content, with a certain degree of magnetic and corrosion-resistant stainless steel belt / sheet, with oxidation resistance, corrosion resistance, good magnetic properties, good plasticity, the higher the purity of nickel, the smaller the resistance, not easy to rust. And other characteristics. Of course, the battery connection piece is possible to use copper, and say copper conductivity is better than nickel, copper in all metal materials, its electrical conductivity is second only to silver. But copper has a disadvantage, is easy to oxidation in the air. If you choose copper to do the connection piece, it needs to do the surface treatment, that is, nickel plating. The nickel strip/sheet will prevent the copper from oxidizing.

In terms of production costs for companies, nickel sheet costs less than copper, is more malleable than copper, and is tougher than copper. Copper nickel plating is good, but less used. Secondly, pure nickel strip, most of the brand-name cell phone batteries are using pure nickel strip, but the price is expensive.

From the connection structure and process, for electric welding, nickel-plated tape is also easier to weld, the welding connection resistance is less than the screw connection, which is the clear advantage of welding. At the same time, the production efficiency of welding can be improved.

From the product properties of nickel-plated steel strip, the purity of 99% nickel will not rust in 20 years. Nickel is highly resistant to corrosion, especially to caustic soda, and nickel does not corrode at a rate of more than 25 microns per year in a 50% boiling caustic soda solution. Nickel also has good strength and plasticity, and can withstand various pressure processing.

Post time: Apr-10-2023