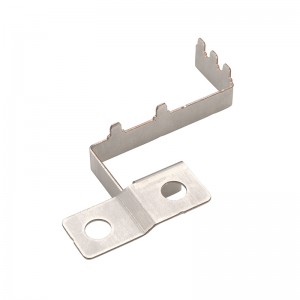

Product Description

| Item name | Stamping Electronic Parts Sheet Metal Components Copper Terminal |

| Material | Copper Alloy, Aluminum Alloy, Stainless Steel, etc. |

| Mold Type | Progressive tool |

| Surface Treatment | Plating, Anodized, Polished, Powder Coated, Painting, etc. |

| Tolerance | as per customers' requirement |

| Quality Assurance | 100% CCD inspection and QC spot check per 2 hours. |

| Process | Stamping, machining, bending, deep drawing, welding, riveting |

| Our Production Cycles | 21 working days for the new mold and within 7 working days for exiting model(Depends on the QTY) |

Custom Stamping Terminal Capabilities

Mingxing has been specialized in high-end electronic connectors, and OEM fabrication services for automotive components, medical equipment parts, and custom accessories based on stamping and assembly processes. With over 24 years of healthy and strong development, Mingxing has been the direct and indirect supplier for many world-famous companies.

At Mingxing, we can provide full range of services for your custom electronic stamped terminals, which includes:

1.Provide OEM/ODM service.

2.Provide professional metal mould design and manufacturing services.

3.Provide metal parts moulding/ painting services.

4.Provide metal parts assembly service.

Q1: Can you introduce your working process and your advantages?

A: Regarding your inquiry, first we will ask for your drawing, requirement, QTY, and more detailed information to understand your demand, so that our engineer can offer the best solution according to these specifications. Then we can start mold design and fabrication when the price settles down, delivery time is approved. About our feature, that we would like to say 100% quality assurance and advantage facilities can give you strong support and our professional service will lead you to make great progress on this project.

Q2: Can you ensure your production lead time and stable quality in a long-term relationship?

A: Of course. Except for the Chinese New Year holiday, our shipment is always on the schedule of our scientific work arrangements, strong production competence, and reliable employee.

Q3: What is the MOQ?

A: Usually we don't set MOQ, but the more, the cheaper. Besides, we are happy to make prototype or sample for clients to ensure quality standard.

-

Factory Price For Wholesale Metal Wall Bracket-...

-

Factory wholesale Suppliers Red Pure Copper Gro...

-

Factory Outlets OEM Green House Hardware Fasten...

-

China Factory for Snb Non-Insulated Tinned Spad...

-

Wholesale Busbar End Insulation Spacer for Busd...

-

Factory Cheap Hot Power Industry Electric Conne...