As technology evolves, the production of medical devices requires more advanced and complex components. This is why precision metal stamping begins to make a difference in the modern medical industry. The medical stamping process helps create the right shape for the smallest metal parts of equipment which are used in hospitals, clinics and even patients’ homes.

When people look at the capabilities that medical device stamping can provide, there are three key points that the manufacturers in medical industry should consider:

1) Accuracy: High-quality medical stamping systems can work with extreme precision, which is crucial for any type of medical device. This means that once the medical device is assembled prior to shipment, all of the components will fit together efficiently. The process starts with the right design, and the machines used in the operation will follow the exact presentation created for each workpiece.

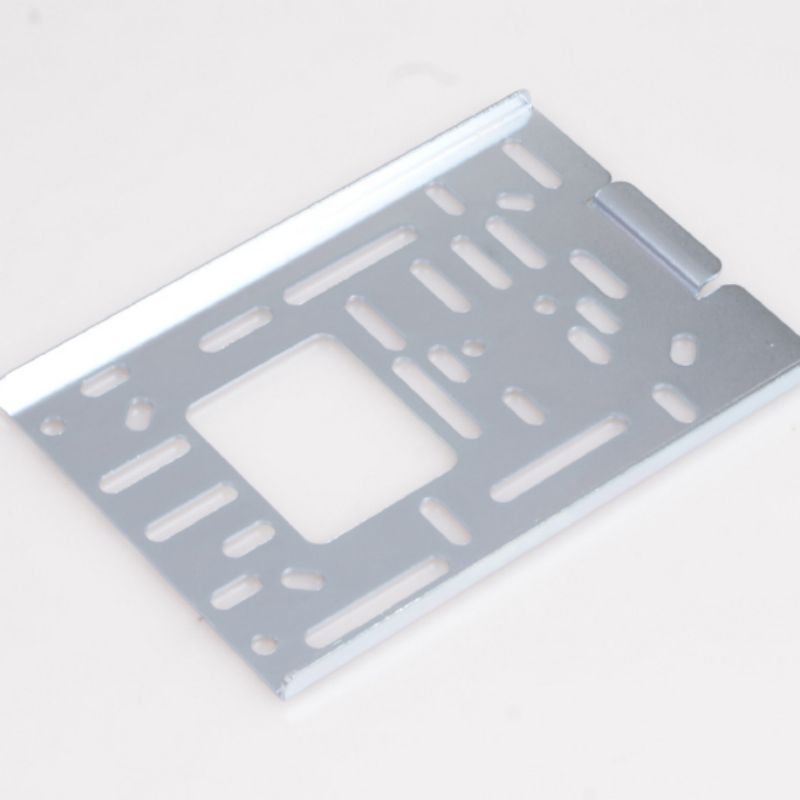

2) Complexity: When metal parts are created by using simple stamping methods or by hand, complex metal parts are often not created correctly. However, with the variety of precision metal stamping machines available, it is easier to get the right shape and size for some of the more complex parts which will be used in medical devices.

3) Quantity: Mass production of these metal parts is another major benefit, as precision hardware stamping allows medical manufacturers to bring more products to market in a shorter period of time. This will give the manufacturer a competitive advantage over their competitors when they are able to launch more products.

Even if medical companies are able to turn to a variety of stamping service providers, the quality of service, customer experience, and precision are not always the same between them. Mingxing Electronic offers superior OEM precision metal stamping services designed to meet every customer need. At Mingxing, the experts are able to use a wide range of materials in the stamping process. This includes stainless steel to provide rust resistance and aluminum to add a lighter touch to medical devices. The stamping services offered by Mingxing also support other steels, such as alloy steels, magnetic materials, and iron.

Post time: Sep-01-2023