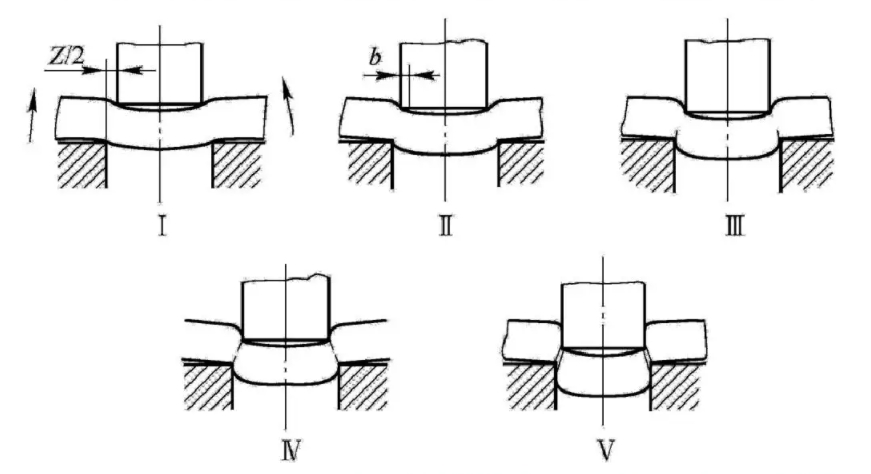

The determination of the reasonable clearance value in stamping production is crucial to achieve desirable results. The reasonable clearance value takes into account several factors, including section quality, dimensional accuracy, and die life of the blanking parts.

The minimum reasonable clearance (Zmin) is the smallest value within the range and should be used when designing and manufacturing new molds. This ensures that the clearance is sufficient to maintain the desired quality and accuracy of the blanked parts while minimizing wear on the dies.

On the other hand, the maximum reasonable clearance (Zmax) represents the largest value within the range. It accounts for the expected increase in clearance due to wear during the production process. As the clearance expands, the risk of burr formation and excessive unloading and ejector forces rises, which can impact the quality of the finished.

Post time: Sep-25-2023