As new energy technologies continue to develop, the application of metal stamping processes in the field of new energy is becoming increasingly widespread. Let’s take a look at some of the applications of metal stamping technology in the field of new energy.

1.Stamping of metallic parts for lithium-ion batteries

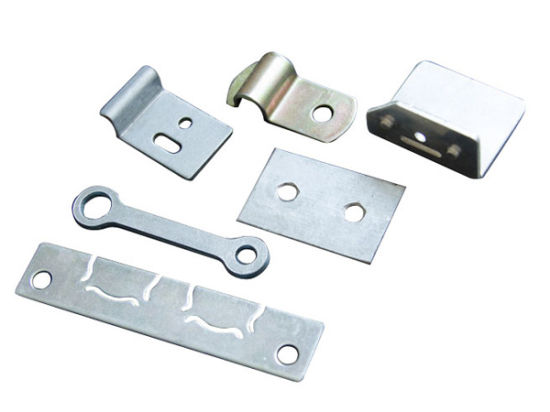

The application of metal stamping technology in the field of lithium-ion batteries is mainly for producing metal stamping parts such as upper and lower cell covers and connection sheets. These metal parts must have high strength and conductivity to ensure the safety and stability of the battery cells. Metal stamping technology can significantly reduce production costs and improve production efficiency, providing important support for the development of the lithium-ion battery industry.

2.Stamping of metallic parts for solar cell modules

Solar cell modules require large quantities of metallic parts, such as aluminum alloy frames, corner pieces, brackets, and connection sheets. These metal parts need to undergo strict precision machining to meet their high strength and anti-corrosion performance requirements. Metal stamping technology not only meets these requirements but also reduces manufacturing costs and improves production efficiency, providing necessary support for the production of solar cell modules.

3.Stamping of metallic parts for new energy vehicles

New energy vehicles require a large number of metal parts, such as battery brackets, chassis brackets, and suspension components. These metal parts need to be lightweight, durable, and have high strength and anti-corrosion performance to adapt to the rapid development of the new energy vehicle industry. Metal stamping technology can improve production efficiency and reduce production costs, providing strong support for the development of the new energy vehicle industry.

In summary, the application of metal stamping technology in the field of new energy is becoming increasingly widespread. This technology not only improves manufacturing efficiency and reduces production costs but also meets the high strength, conductivity, and anti-corrosion performance requirements of metal parts in the new energy field. With the continuous advancement of technology, we believe that metal stamping processes in the field of new energy will become even more widespread and deep-rooted.

Post time: Jun-02-2023