Design principles play a crucial role in the process of designing metal stamping parts. By adhering to appropriate design principles, it is possible to ensure that the final product exhibits excellent quality, performance, and reliability. Here are some key design principles to consider when designing metal stamping parts:

Material Selection: Choosing the right material is critical to the performance and cost of metal stamping parts. Different materials have distinct mechanical properties and processing characteristics, so the selection should take into account the part’s intended use, stress conditions, and environmental factors.

Minimize Material Waste: When designing metal stamping parts, efforts should be made to minimize material waste, thereby increasing material utilization and reducing costs. Through strategic layout and optimized design, waste generation can be minimized.

Structural Integrity: Structural design should fully consider the functional requirements of the part, avoiding stress concentration or other potential weaknesses. A well-considered structural design can enhance the part’s strength and rigidity, extending its service life.

Manufacturer ability Considerations: The design process should take manufacturer ability into account, including material availability, processing methods, and tooling design. Only by considering these factors can the designed part smoothly transition into production.

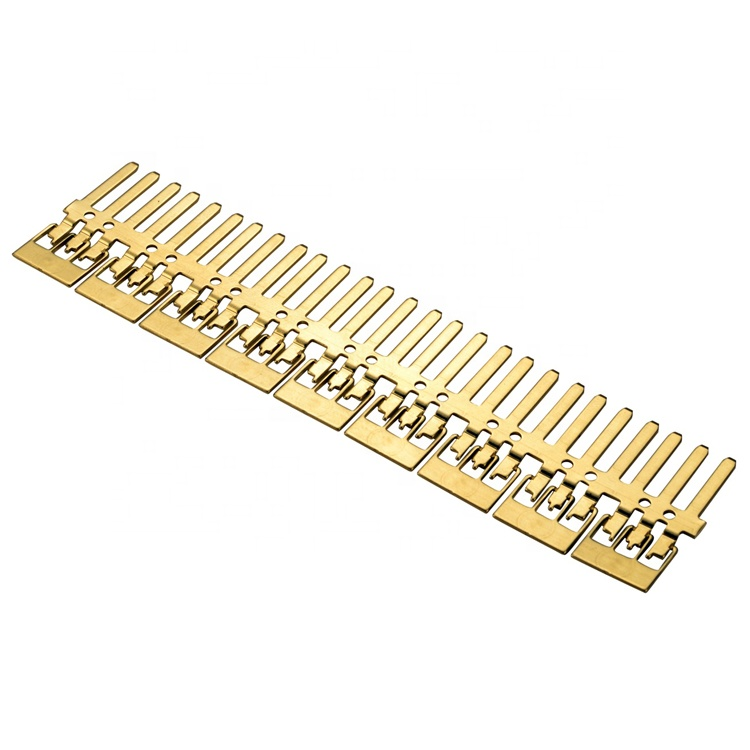

Surface Treatment: Appropriate surface treatment can enhance the corrosion resistance and aesthetics of the part, as well as improve surface friction and lubrication properties. Therefore, surface treatment needs to be fully considered in the design process.

In conclusion, the design principles for metal stamping parts encompass various aspects, requiring thorough consideration of material selection, structural design, manufacturer ability, and surface treatment. Only by addressing these factors during the design phase can the quality and performance of the parts be maximized, production costs reduced, and market competitiveness enhanced.

Post time: Nov-14-2023