Heat sinks are sheet-like objects made of metallic materials used for heat dissipation and conduction, which are used to increase the surface area for heat dissipation and enhance heat conduction. According to different shapes and structures, heatsinks can be divided into the following types:

Heat sink sheet type radiator: it consists of a series of sheet-like metal pieces, usually made of copper or aluminum, which can effectively increase the surface area and improve the heat dissipation efficiency. It is produced mainly by cutting or water jet cutting the metal sheets and then surface treating the sheet metal.

Heat sink finned radiator: It consists of sheet metal and short fins to increase the surface area for heat dissipation while reducing the size. Common production methods include mold metal pressing or press forming.

Heat pipe radiator: It consists of one or more metal pipes filled with heat conducting medium inside, which can rapidly conduct heat to the whole surface of the pipe and dissipate heat by convection of fluid. The production method is mainly made by bending, cutting, welding and other processes of metal tubes.

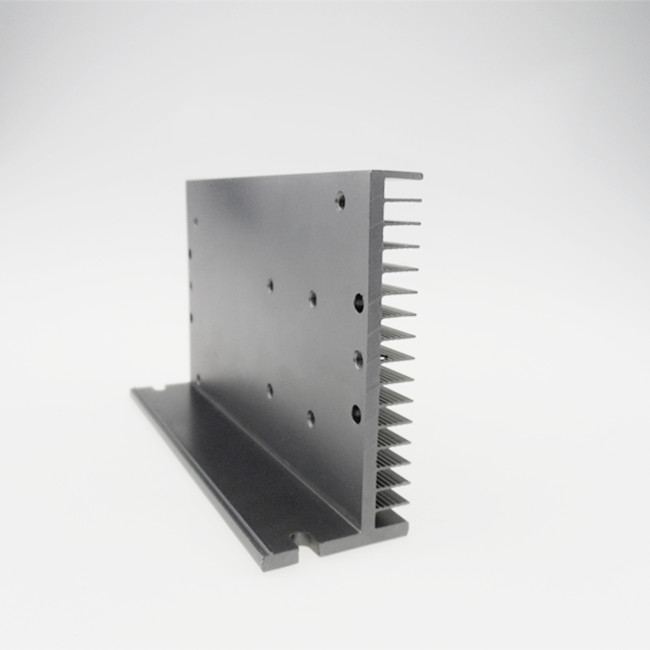

Heat dissipation finned radiator: It consists of fins and base, and improves heat dissipation efficiency by increasing the number and surface area of fins. Common production methods include casting, extrusion, forging and other processes.

Heat sink and fan are used in a wide range of applications, including electronic devices (e.g., computers, cell phones, etc.), automotive engines, aerospace equipment, cooling equipment (e.g., air conditioners, refrigerators, etc.), optoelectronic devices, and other fields. They can help conduct heat quickly into the heat sink medium and dissipate it through the flow or convection of the heat sink medium, ensuring the normal operating temperature of the equipment and extending its service life.

Post time: Aug-08-2023