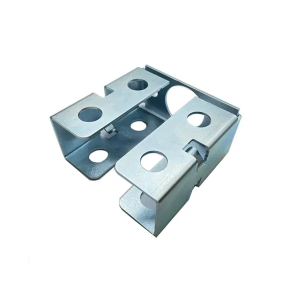

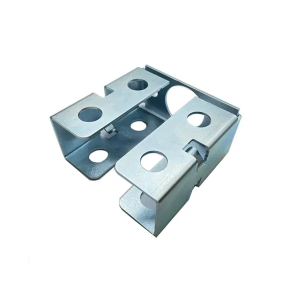

Product Specifications

| Dimension | Customize |

| Material | Stainless Steel, Carbon Steel, Iron, Aluminum or Customized |

| Surface Treatment | Plating, Painting, Powder Coating, Polishing, Brushing, etc. |

| Application | Aviation Industry, Military Industry, Machinery Industry, Agricultural Machinery Industry, Railway Industry, Post and Telecommunications Industry, Transportation Industry, Chemical Industry, Medical Equipment Industry, Household Industry |

| Quality Control | ISO9001:2015 |

| Equipments | CNC Stamping/Punching Machine, CNC Bending Machine, CNC Cutting Machine, 5-300T Punching Machines, Welding Machine, Polish Machine, Lathe Machine |

| File Format | Solidworks, Pro/Engineer, Auto CAD, PDF, JPG |

| Service | IQC, IPQC, FQC, QA |

| Thickness | 0.08mm~1mm, or other special available |

| Sample Confirmation | Before starting mass production, we will send pre-production samples to the customer for confirmation. We will modify the mold until the customer is satisfied. |

| Packing | Inner Plastic Bag; Outer Standard Carton Box or Customized |

Product Description

Solution

Provide the best solution to customer.

Quality

Provide best quality product to customer.

Price

Reasonable price for customer, make win-win relationship.

Delivery

Quickly &safety delivery by all sort of transport mode.

Cooperation Mission

We win our customer by excellent quality, competitive price, prompt delivery, best solution.

NOTE:

One of our features is that stamping products are customized according to clients' requirement

1. Good package design to protect stainless steel sheet metal fabrication parts .

1) Industrial Package: Plastic Film+Carton+Wooden Pallet

2) Commercial Package: Plastic Bag/Film+Carton+Wooded Pallet

3) As the clients requirements

2. We can arrange all kind of transportation to ship stainless steel sheet metal fabrication parts with low freight.For example DHL,UPS,TNT,FEDEX express,or by sea as your required.

Q. Are you a factory or a trade company?

A:We're a factory with over 20 years experience in the heat sink field.It is a enterprise that professionally design and produce Heat sinks, electronic components, auto parts and other stamping products.

Q. How to get a quotation?

A: Please send us info such as drawing,material surface finish,quantity.

Q. What about the lead time?

A: Average for 12 working days, open mould for 7 days and mass production for 10 days

Q. Do the products of all the colors are the same with same surface treatment?

A: No. about powder coating, the bright-color will higher than white or gray. About the Anodizing, colorful will higher than silver, and black higher than colorful.

-

ISO-Certified Manufacturer of Carbon Steel Shee...

-

High-Quality Precision Metal Stamping Manufactu...

-

Sheet Metal Fabrication Services for Aluminum a...

-

Factory OEM Metal Stamping Parts Aluminum Steel...

-

Customized Sheet Metal Fabrication Aluminum Sta...

-

Custom Galvanized Zinc Plated Metal Thin Shim ...