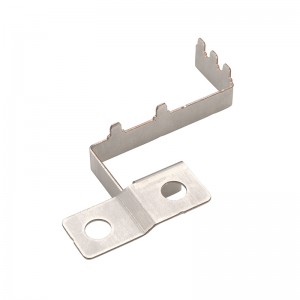

Product Description

| Item name | Custom Metal Stamping Copper Busbars for BMS Battery |

| Material | Copper Alloy, C1100, Brass, Aluminum Alloy, etc. |

| Mold Type | Progressive tool |

| Surface Treatment | Tin Plating or no plating |

| Tolerance | as per customers' requirement |

| Quality Assurance | 100% CCD inspection and QC spot check per 2 hours. |

| Process | Stamping, machining, bending, deep drawing, welding, riveting |

| Mass production | 21 working days for the new mold and within 7 working days for exiting model after receipt of deposit. (Depends on the QTY) |

Custom Stamping Copper Bus bar Capabilities

Mingxing is one of the precision metal stamping manufactures of flexible copper connectors in China. Founded in 1998, we have decades of experience and technology in manufacturing flexible copper connectors for Chinese and International clients, and provide them with the professional electrical conduction and earthing solutions.

Mingxing owns modernazed workshops covering an area of 4000 square meters and 50 staffs including 20 professional technicians and QC. Our highly qualified engineers gurantee the quality in the whole process of production. At Mingxing, we can provide full range of services for your custom electronic stamped copper ground bus bar, which includes:

1.Provide OEM/ODM service.

2.Provide professional metal mould design and manufacturing services.

3.Provide metal parts moulding/ painting services.

4.Provide metal parts assembly service.

Q1: Are you a direct manufacturer?

A:Yes, we are direct metal stamping manufacturer. We have been in this domain since 1998. And if you want, we could chatting with you on video via Wechat/Whatsapp/Messenger and any way you like to show you our plant.

Q2: How can you guarantee quality?

A: Always a pre-production sample before mass production;

Always 100% inspection before shipment;

Q3: What kind of service/products you provide?

A: Service of OEM/ one-stop service/ assembly; From mold design, mold making, machining, fabrication, welding, surface treatment, assembly, packing to shipping.