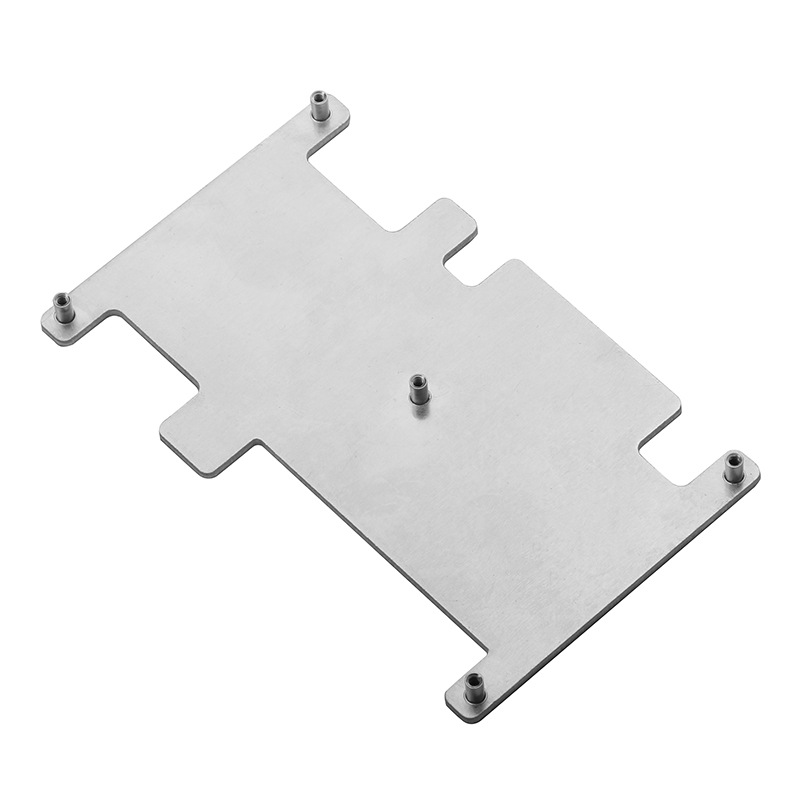

Low MOQ for Zinc Tin Plating - Custom Stamping Service Aluminum Heat Sink For EV battery management system – Mingxing Detail:

Key Specifications/ Special Features

Example of product as you required

1. Small quantity is accepted

2. Specification: according to customer’s drawing or sample, pictures

3. OEM or ODM are welcome

4. Machined material: steel, cold roll steel, mild steel, stainless steel, aluminum, copper, brass

5. Finished/surface treatment: painting, nickel-plating, zinc-plating, galvanized, anodized, brushed, polished, and more

Process flows

Step 1-make tooling

Step 2-stamp the main body

Step 3-inner inspection

Step 4-deburr and tin plating

Step 5-outgoing inspection

Here I give the brief introduction to the manufacturing procedure;

Advantages

– High-Quality for raw material: all raw materials are purchased from reliable manufacturers, the material specification will be exactly as required, absolutely no adulterate

–Own moulding/tooling room: We can make or modify the molding/tooling as per as customer’s requirements

–Strict SOP: The SOP is the key of the complete delivery project ,each procedure for the Item production is strictly followed on the working instruction and the finalize official drawings, all operation will complete exactly as the SOP

–Comprehensive QC: QC run through the whole production flow, so the defects can be avoided by the first time

–Suitable packing:To be packed in strong wooden cases/cartons suitable for transport by air/sea Freight, according to International Standards

–Regular training: to give the best service to all clients, we have special room for inner training which cover various topics: QC, production control, operation flow, service

--Company Culture : We usually organize various kind of the exercises,the festival parties and the other sports to encourage staff keep the good health and spend the high efficiency to involve in work . Each Staff have the high passion to enjoy his job

For the fast results, when requesting a quote ,it will be proceeded by following steps ;

A.Provide the drawings which cover the material ,surface treatment ,detail dimension (Dwg or PDF format)

B.If no any drawings,the sample is the options

Project assessment by our Engineering department

C.Confirm the drawings before the sample making

D.Clarification the sample and finalized before the mass production

FAQ

FREQUENTLY ASKED QUESTIONS

Q. Are you a factory or a trade company?

A:We’re a factory with over 20 years experience in the heat sink field.It is a enterprise that professionally design and produce Heat sinks, electronic components, auto parts and other stamping products.

Q. How to get a quotation?

A: Please send us info such as drawing,material surface finish,quantity.

Q. What about the lead time?

A: Average for 12 working days, open mould for 7 days and mass production for 10 days

Q. Do the products of all the colors are the same with same surface treatment?

A: No. about powder coating, the bright-color will higher than white or gray. About the Anodizing, colorful will higher than silver, and black higher than colorful.

Product detail pictures:

Related Product Guide:

Our solutions are widely recognized and trusted by consumers and will meet up with constantly developing financial and social requires for Low MOQ for Zinc Tin Plating - Custom Stamping Service Aluminum Heat Sink For EV battery management system – Mingxing, The product will supply to all over the world, such as: Tunisia, Kuala Lumpur, Norwegian, We've customers from more than 20 countries and our reputation has been recognized by our esteemed customers. Never-ending improvement and striving for 0% deficiency are our two main quality policies. Ought to you want anything, don't hesitate to contact us.

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!

-

Hot sale Factory Copper Busbar Ampacity - Stai...

-

Hot sale Arc Anodizing - Custom Stamping Sheet...

-

One of Hottest for Nickel Electro Plating - St...

-

Professional Design Stamping Wiki - Lithium Ba...

-

China New Product Metal Stamping For Automotive...

-

Original Factory A Heat Sink Is Generally Used ...