Izingxenyekazi zekhompuyuthaukunyathelafaisebenzisa izinto ezihlukahlukene zensimbi nezingezona ezensimbi, ikakhulukazi okuyi-carbon steel, i-alloy steel, insimbi ecijile, insimbi ecijile, i-hard alloy, i-low melting point alloy, i-alloy-based alloy, i-aluminium bronze, njll.

Izinto zokukhiqiza izitembu ze-hardware ziyafa zidinga ubulukhuni obuphezulu, amandla aphezulu, ukumelana nokugqoka okuphezulu, ukuqina okufanele, ukuqina okuphezulu nokwelashwa kokushisa ngaphandle kokuguqulwa (noma ukuguqulwa okuncane) nokucisha akulula ukuqhekeka nezinye izakhiwo.

Ukukhetha okunengqondo kwezinto zokufa zokunyathela izitembu zehadiwe kanye nokuqaliswa kwenqubo efanele yokwelapha ukushisa kuyisihluthulelo sokuqinisekisa impilo yefa.Omafa anezinhlelo zokusebenza ezihlukene, kufanele acatshangelwe ngokwesimo sawo sokusebenza, izimo zokucindezelwa kanye nokusebenza kwempahla ecutshunguliwe, umthamo wokukhiqiza nokukhiqiza, njll., futhi kugxilwe ezidingweni zokusebenza ezishiwo ngenhla, bese kwenziwa okuhambisanayo. ukukhetha kwensimbi kanye nenqubo yokwelapha ukushisa.

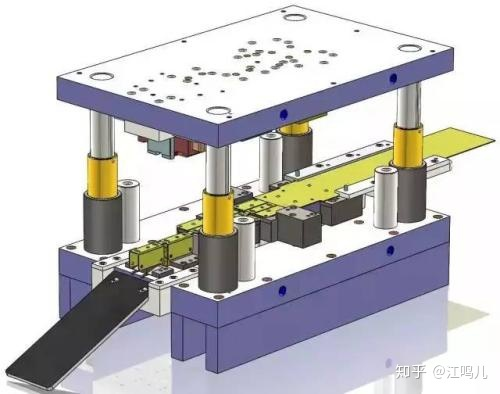

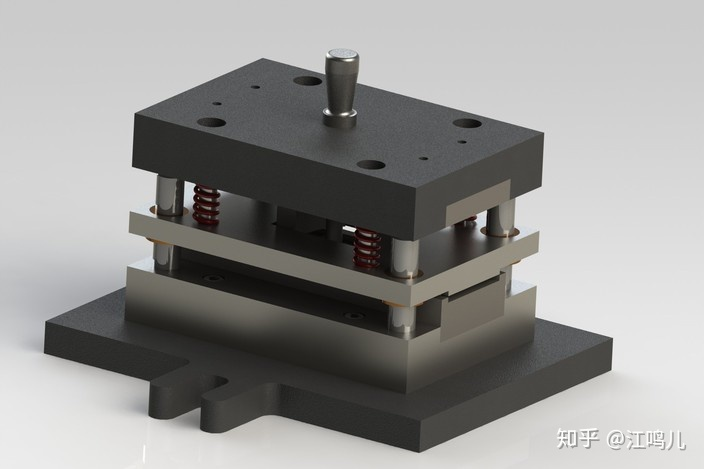

Lapho iqoqo ukukhiqizwa ocebile futhi epheleleizingxenye zokunyathelainkulu, izinto zokwakha zezingxenye zokusebenza zediyizi zezingxenye zokugxiviza zehadiwe, njenge-convex die kanye ne-concave die, kufanele zikhethwe ensimbi yokufa enekhwalithi ephezulu kanye nokumelana okuhle kokugqoka.Ukuze uthole izinto zezingxenye zezinye izingxenye zesakhiwo senqubo kanye nezingxenye zesakhiwo esiwusizo ze-die, kufanele futhi zithuthukiswe ngokufanele.Uma iqoqo lingelikhulu, imfuneko yokusebenza kwempahla kufanele ixegiswe ngendlela efanele ukuze kwehliswe izindleko.

Lapho izinto okufanele zicindezelwe futhi zicutshungulwe ziqinile noma ukumelana ne-deformation kukhulu, i-convex ne-concave iyafaukufa ngesibhakelakufanele zenziwe ngezinto ezinokumelana okuhle kokugqoka namandla aphezulu.Uma udweba insimbi engagqwali ejulile, i-aluminium bronze concave die ingasetshenziswa ngoba inendawo engcono yokunamathela.Isihlahla sensika yomhlahlandlela sidinga ukumelana nokugqokwa kanye nokuqina okuhle, ngakho-ke ukucisha i-carbon steel surface carburization quenching.

Ezingxenyeni zohlobo lwepuleti elilungisiwe kanye nokukhishwa kwepuleti, akufanele nje zibe namandla anele, kodwa futhi zidinga ukuguqulwa okuncane phakathi nenqubo yokusebenza.Ngaphezu kwalokho, ungasebenzisa futhi ukwelashwa okubandayo kanye nokwelashwa okubandayo okujulile, ukwelashwa kwe-vacuum nezindlela zokuqinisa ubuso ukuze uthuthukise ukusebenza kwezingxenye zesikhunta.Ukuze convex, concave die izimo zokusebenza abampofu extrusion abandayo kufa, kufanele kukhethwe ngobulukhuni obanele, amandla, ukuqina, ukumelana bafake kanye nezinye izici olunzulu mechanical of okuhle die steel, kuyilapho kufanele kube nobulukhuni ezithile obomvu kanye ezishisayo amandla ukukhathala, njll.

Isikhathi sokuthumela: Jan-10-2023