Hardwareisitampufaisebenzisa izinto ezahlukeneyo zetsimbi kunye nezingezona zetsimbi, eziziintsimbi zekhabhoni, intsimbi yensimbi, intsimbi ekhandiweyo, intsimbi ekhandiweyo, intsimbi eqinile, i-alloy ephantsi yokunyibilika, i-zinc-based alloy, i-aluminium bronze, njl.

Izinto eziphathekayo ze-hardware stamping ziyafa zifuna ubunzima obuphezulu, amandla aphezulu, ukumelana nokunxiba okuphezulu, ukuqina okufanelekileyo, ukuqina okuphezulu kunye nonyango lobushushu ngaphandle kokuguqulwa (okanye ukuguqulwa okuncinci) kunye nokucima akukho lula ukuqhekeka kunye nezinye iipropati.

Ukhetho olufanelekileyo lwezixhobo ze-hardware stamping die kunye nokuphunyezwa kwenkqubo echanekileyo yonyango lobushushu ngundoqo wokuqinisekisa ubomi bokufa.Kuba ifa kunye nezicelo ezahlukeneyo, kufuneka kuthathelwe ingqalelo ngokwemeko yayo yokusebenza, iimeko zoxinzelelo kunye nokusebenza kwezixhobo ezicwangcisiweyo, umthamo wemveliso kunye nemveliso, njl. ukhetho lwensimbi kunye nenkqubo yokunyanga ukushisa.

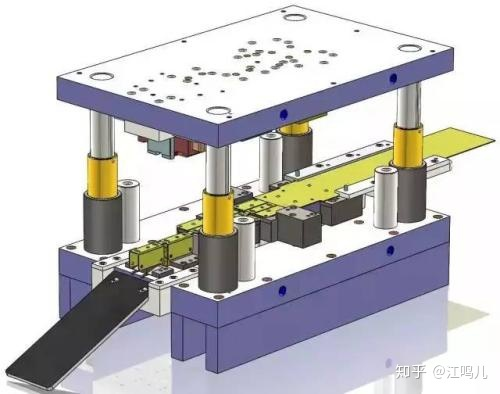

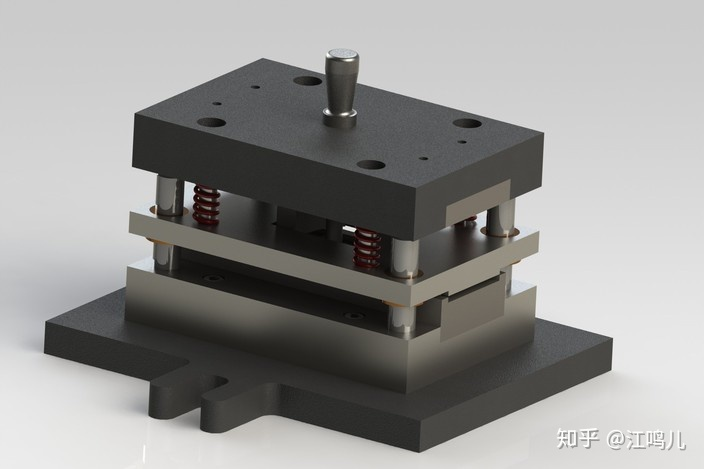

Xa ibhetshi imveliso osisityebi kwaye epheleleyoiindawo zokunyathelainkulu, izinto zeendawo zokusebenza ze-die for hardware stamping parts, ezifana ne-convex die kunye ne-concave die, kufuneka zikhethwe kwintsimbi yokufa enomgangatho ophezulu kunye nokumelana nokunxiba okulungileyo.Kwizinto zezixhobo zezinye iindawo zesakhiwo senkqubo kunye neengxenye zesakhiwo ezincedisayo zokufa, kufuneka ziphuculwe ngokufanelekileyo.Xa ibhetshi ingekho nkulu, imfuno yokusebenza kwezinto kufuneka ikhululeke ngokufanelekileyo ukunciphisa iindleko.

Xa izinto eziza kucinezelwa kwaye zicutshungulwe zinzima okanye ukuchasana kwe-deformation kukhulu, i-convex kunye ne-concave iyafa.ukufa ngenqindikufuneka zenziwe ngezinto eziphathekayo ezinokumelana nokunxiba kakuhle kunye namandla aphezulu.Xa uzoba intsimbi enzulu, i-aluminium bronze concave die ingasetyenziswa kuba inepropathi engcono yokuchasana.Isikhokelo sentsika yesikhokelo sifuna ukuxhathisa ukunxiba kunye nokuqina okuhle, ngoko ke ngakumbi i-carbon steel surface carburization quenching.

Kwiplate esisigxina kunye neengxenye zeplate yokukhupha, akufanele nje ukuba babe namandla okwaneleyo, kodwa kufuneka bafune i-deformation encinci ngexesha lenkqubo yokusebenza.Ukongeza, ungasebenzisa unyango olubandayo kunye nonyango olubandayo, unyango lwe-vacuum kunye neendlela zokuqinisa umphezulu wokuphucula ukusebenza kweendawo zokubumba.Kuba convex, concave die iimeko zokusebenza amahlwempu extrusion ebandayo kufa, kufuneka zikhethwe ngobulukhuni ngokwaneleyo, amandla, ukuqina, ukuxhathisa banxibe kunye nezinye iimpawu ezibanzi mechanical of elungileyo die intsimbi, lo gama kufuneka ibe nobulukhuni ethile ebomvu kunye thermal ukudinwa amandla, njl.

Ixesha lokuposa: Jan-10-2023