Hardwarestampingkufainoshandisa simbi dzakasiyana-siyana uye dzisiri simbi zvinhu, zvinonyanya kabhoni simbi, alloy simbi, simbi yakakandwa, simbi yakakandwa, hard alloy, low melting point alloy, zinc-based alloy, aluminium bronze, nezvimwe.

Zvinhu zvekugadzira Hardware stamping inofa inoda kuomarara kwakanyanya, kusimba kwepamusoro, kushomeka kwepamusoro, kuomarara kwakakodzera, kuomarara kwepamusoro uye kurapwa kwekupisa pasina deformation (kana kushomeka deformation) uye kudzima hakusi nyore kutsemuka uye zvimwe zvinhu.

Kusarudzwa kunonzwisisika kwe Hardware stamping die materials uye kuitwa kweiyo chaiyo kupisa kupisa maitiro ndiyo kiyi yekuve nechokwadi chehupenyu hwekufa.Kune avo vanofa vaine mashandisirwo akasiyana, inofanirwa kutariswa zvinoenderana nemamiriro ekushanda, mamiriro ekushushikana uye kuita kwezvinhu zvakagadziriswa, vhoriyamu yekugadzira uye kubereka, nezvimwewo, uye tarisa pane zvataurwa pamusoro pekuita zvinodiwa, wobva wagadzira zvinoenderana. kusarudzwa kwesimbi uye kupisa kurapa maitiro.

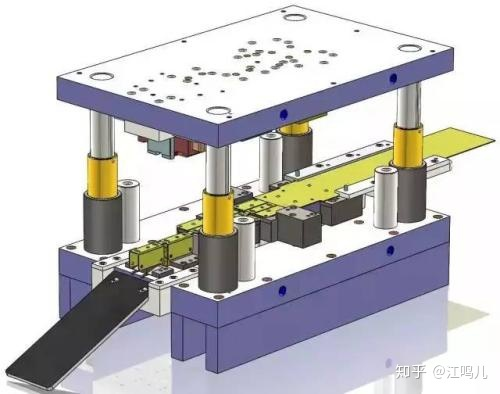

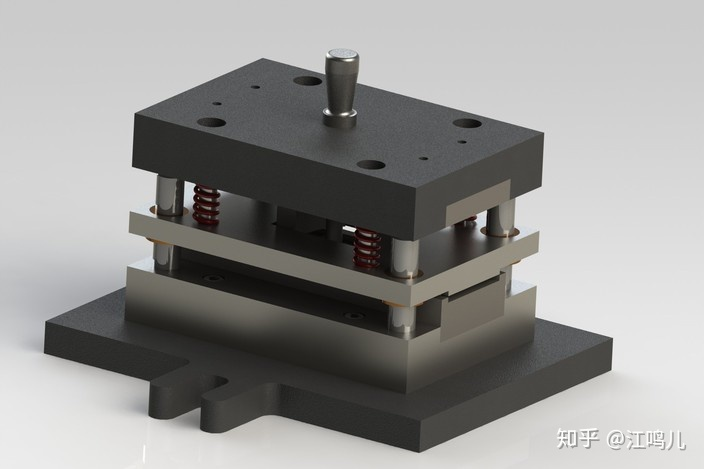

Kana kugadzirwa batch yevapfumi uye yakakwanakutsika zvikamuyakakura, zvinhu zvezvikamu zvekushanda zvefa kune hardware stamping zvikamu, senge convex die uye concave die, zvinofanirwa kusarudzwa kubva mufire simbi ine mhando yepamusoro uye yakanaka kupfeka kuramba.Zvemidziyo yezvimwe zvikamu zveimwe process dhizaini zvikamu uye zvekubatsira chimiro zvikamu zvefa, ivo vanofanirwawo kuvandudzwa zvinoenderana.Kana iyo batch isiri yakakura, chinodiwa chekuita kwezvinhu chinofanira kurerutswa nenzira kwayo kudzikisa mutengo.

Kana iyo zvinhu zvekudzvanywa uye kugadziriswa zvakaoma kana deformation kuramba yakakura, iyo convex uye concave inofakurova kufainofanira kugadzirwa nezvinhu zvakanaka kupfeka kuramba uye simba guru.Kana uchidhirowa yakadzika simbi isina tsvina, aluminium bronze concave die inogona kushandiswa nekuti ine zvirinani anti-adhesive pfuma.Iyo inotungamira mbiru yegwara gwenzi inoda kupfeka kuramba uye kusimba kwakanaka, saka yakaderera kabhoni simbi pamusoro carburization quenching.

Kune yakagadziriswa ndiro uye discharge plate type parts, kwete chete kuti dzive nesimba rakakwana, asi dzinodawo zvishoma deformation panguva yekushanda.Uye zvakare, iwe unogona zvakare kushandisa inotonhora kurapwa uye yakadzika kutonhora kurapwa, vacuum kurapwa uye pamusoro pekusimbisa nzira nzira dzekuvandudza mashandiro ezvikamu zvekuumbwa.Kune convex, concave die work condition yakashata inotonhora extrusion kufa, inofanira kusarudzwa nekuoma kwakakwana, simba, kuomarara, kupfeka kuramba uye mamwe akakwana emuchina zvimiro zveakanaka die simbi, nepo inofanirwa kuve nehumwe hutsvuku hwekuoma uye nekupisa kuneta simba, nezvimwe.

Nguva yekutumira: Jan-10-2023