Ukuthuthukiswa kuyaqhubeka ukwenzeka kubuchwepheshe bebhethri yamandla amasha, okuholela ekushintsheni kwezimfuneko zezingxenye zesakhiwo sebhethri.Njengamanje, abakhiqizi abaningi bebhethri ye-lithium bashisela imichilo yethusi emigqeni ye-aluminium exhuma ama-electrode ebhethri.Ezindleleni zokucubungula zendabuko, ukushisela okusebenzayo phakathi kwemichilo yethusi ne-aluminium kuvinjelwa ukulinganiselwa kwezinto ezibonakalayo, okungaholela ekushiseleni okungaphumeleli, amandla anganele wokushisela, noma izindleko eziphakeme ngendlela enqatshelwe.

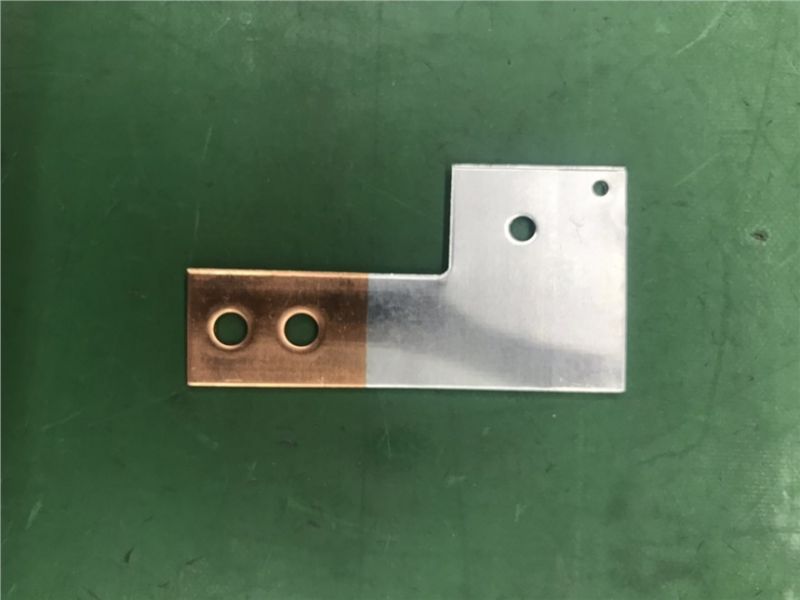

Ukuze kuhlangatshezwane nezidingo zamakhasimende nezemakethe, ithimba lezobuchwepheshe e-Dongguan Mares lisebenzise imishini yokusabalalisa amangqamuzana ukuze lifinyelele ukushisela phakathi kwemichilo ye-aluminium neyethusi.Imiphumela ye-welding iboniswa esithombeni esingenhla: ukubukeka kuhlanzekile, i-weld seam incane, futhi amandla okudonsa aphezulu.Lo mkhiqizo wamukelwe futhi waqashelwa amakhasimende amaningi ebhethri lamandla amasha.

Ubuchwepheshe be-molecular diffusion welding bubonisa imiphumela emihle kakhulu uma busetshenziswa ezintweni eziningi zensimbi, ikakhulukazi ezinsimbi zokushisela ezinomoya oshisayo ophakeme njenge-aluminium, ama-alloys e-aluminium, nethusi, okuqinisekisa izinga eliphezulu nokuthembeka.

Ukushisela phakathi kwemichilo yethusi ne-aluminium kulungele ngokuyinhloko ukuxhumana ubuso nobuso.Ngenxa ye-aluminiyamu esebenza kabusha kakhulu, ijwayele ukungena nge-oxidation ngesikhathi senqubo yokushisela.Ngakho-ke, ukulawula okunembile kokushisa kwe-welding kanye nesikhathi kubalulekile ukuvimbela ukuhlanekezela kwemichilo yethusi-aluminium.

Ukuhlanza kwangaphambili kwe-welding:

Ngaphambi kokwenza i-diffusion welding, izinto zokusebenza ezinamabala kawoyela phezu kwemichilo yethusi-aluminium kufanele zihlanzwe ngezincibilikisi eziphilayo noma umhwamuko we-organic solvent (njenge-acetone).Ungqimba lwe-oxide phakathi kwebanga elingu-10mm lendawo yokushisela kufanele luhlanzwe kahle kusetshenziswa i-metallographic sandpaper noma amafayela we-emery, ikakhulukazi indawo engaphakathi yelunga.

Inqubo yokushisela:

Ukugcina ukuqondana okungaguquguquki kwezingcezu zokusebenza ze-copper-aluminium strip endaweni efanele kuyo yonke inqubo yamangqamuzana okusabalalisa kubalulekile ukuze kuqinisekiswe ukunemba okusebenzayo.Lokhu ngokuvamile kungafezwa kusetshenziswa izinto zokumisa, noma ngosizo lwezinye izinto ezisizayo.Ukubala izinga lokushisa lokushisela nokubamba isikhathi sokucindezela ngokusekelwe kugqinsi lokushisela kanye nendawo yokuthintana yamapheshana ethusi ne-aluminium kubalulekile ukuze kuvinjelwe izinkinga zekhwalithi ezifana nokuguquka kokushisa.

Isikhathi sokuthumela: Oct-19-2023