Ukuphumelela kuyaqhubeka ukwenzeka kwitekhnoloji yebhetri yamandla amatsha, okukhokelela ekutshintsheni kweemfuno zamalungu ebhetri.Okwangoku, abaninzi abavelisi bebhetri ye-lithium badibanisa imicu yobhedu kwimicu ye-aluminium edibanisa i-electrode yebhetri.Kwiindlela zokucutshungulwa kwendabuko, i-welding esebenzayo phakathi kwe-copper kunye ne-aluminium strips ithintelwa yimida yezinto eziphathekayo, mhlawumbi ibangele i-welding engaphumeleli, amandla aneleyo e-welding, okanye iindleko eziphezulu ngokunqatshelwe.

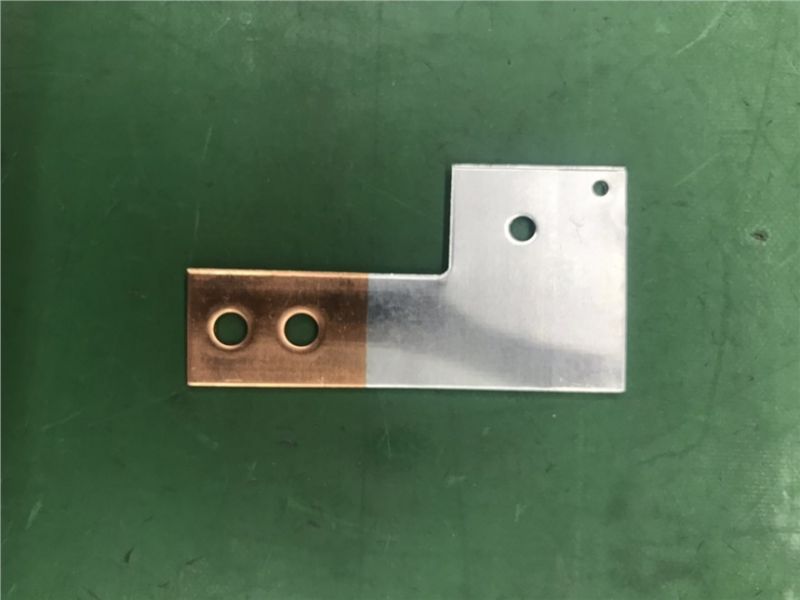

Ukuze kuhlangatyezwane neemfuno zabathengi kunye neemarike, iqela lobuchwephesha e-Dongguan Mares lisebenzise izixhobo zokusasaza iimolekyuli ukuphumeza ukuwelda phakathi kwe-aluminiyam kunye nemicu yobhedu.Iziphumo ze-welding ziboniswe kumfanekiso ongentla: ukubonakala kucocekile, i-weld seam incinci, kwaye amandla okutsala aphezulu.Le mveliso yamkelwe kwaye yamkelwa ngabathengi abaninzi bebhetri yamandla amatsha.

Itekhnoloji ye-molecular diffusion welding ibonisa iziphumo ezigqwesileyo xa isetyenziswa kwizinto ezininzi zetsimbi, ngakumbi kwiintsimbi zokuwelda ezine-thermal conductivity ephezulu efana ne-aluminium, i-alloys ye-aluminium, kunye nobhedu, iqinisekisa umgangatho ophezulu kunye nokuthembeka.

I-Welding phakathi kwemicu yobhedu kunye ne-aluminiyam ifanelekile ngokuyintloko ukudibanisa ubuso nobuso.Ngenxa ye-aluminiyam ephezulu yokuphinda isebenze, idla ngokuthanda i-oxidation ngexesha lenkqubo ye-welding.Ke ngoko, ukulawulwa ngokuchanekileyo kobushushu be-welding kunye nexesha kubalulekile ukuthintela ukugqwethwa kwemicu yobhedu-aluminiyam.

Ukucoca kwangaphambili:

Ngaphambi kokwenza i-welding ye-diffusion, izixhobo zokusebenza ezinamabala e-oyile kumphezulu wemicu yobhedu-aluminiyam kufuneka zicocwe ngezinyibilikisi zendalo okanye umphunga we-organic solvent (njenge-acetone).Uluhlu lwe-oxide ngaphakathi koluhlu lwe-10mm yendawo ye-welding kufuneka ihlambuluke ngokucokisekileyo usebenzisa i-metallographic sandpaper okanye iifayile ze-emery, ngokukodwa indawo yangaphakathi yokudibanisa.

Inkqubo yeWelding:

Ukugcina ulungelelwaniso olungaguqukiyo lwemicu yobhedu-aluminiyam kwindawo efanelekileyo kuyo yonke inkqubo yokusasazwa kweemolekyuli kubalulekile ekuqinisekiseni ukuchaneka okusebenzayo.Oku kunokufezekiswa kusetyenziswa izixhobo zokubeka, okanye ngoncedo lolunye oluncedisayo.Ukubala ukushisa kwe-welding kunye nokubamba ixesha loxinzelelo olusekelwe kwi-welding thick and contact area of copper and aluminium strips kubalulekile ukukhusela imiba esemgangathweni efana ne-thermal deformation.

Ixesha lokuposa: Oct-19-2023