I-Stamping yinkqubo yokuqulunqa exhomekeke kwii-presses kwaye ifa ukuze isebenzise amandla angaphandle kwiipleyiti, imichilo, imibhobho kunye neeprofayili ukuvelisa i-deformation yeplastiki okanye ukuhlukana ukuze kufumaneke ii-workpieces zemilo efunekayo kunye nobukhulu.Ngokweemeko zenkqubo ezahlukeneyo, inkqubo yesitampu ineendlela ezahlukeneyo zokuhlela.Makhe sazise ngokufutshane ukuba zeziphi iintlobo zeintsimbiinkqubo yokunyathelakokulandelayo.

1.Ngokomsebenzi ogqityiweyo ukwahlulahlula:

Inkqubo yesitampu inokwahlulwa ngokurhabaxa ibe ngamacandelo amabini ngokuhambelana nomsebenzi ogqityiweyo: inkqubo yokwahlula kunye nenkqubo yokwenza (ikwahlulwe ngokugoba, ukuzoba kunye nokwenza).

2.Ngokobushushu beisitampuukwahlula-hlula:

Kukho iindidi ezimbini zokunyathela, ukunyathela okubandayo kunye nokushisa okutshisayo, ngokwemeko yobushushu ngexesha lokunyathela.Oku kuxhomekeke kumandla, iplastiki, ubukhulu, iqondo lokuguqulwa kunye nomthamo wesixhobo sezinto eziphathekayo, njl njl. Isimo sokuqala sokushisa ubushushu bezinto kunye neemeko zokugqibela zokusetyenziswa kufuneka ziqwalaselwe.

3. Ukuhlelwa ngokwesakhiwo seukufa ngenqindi:

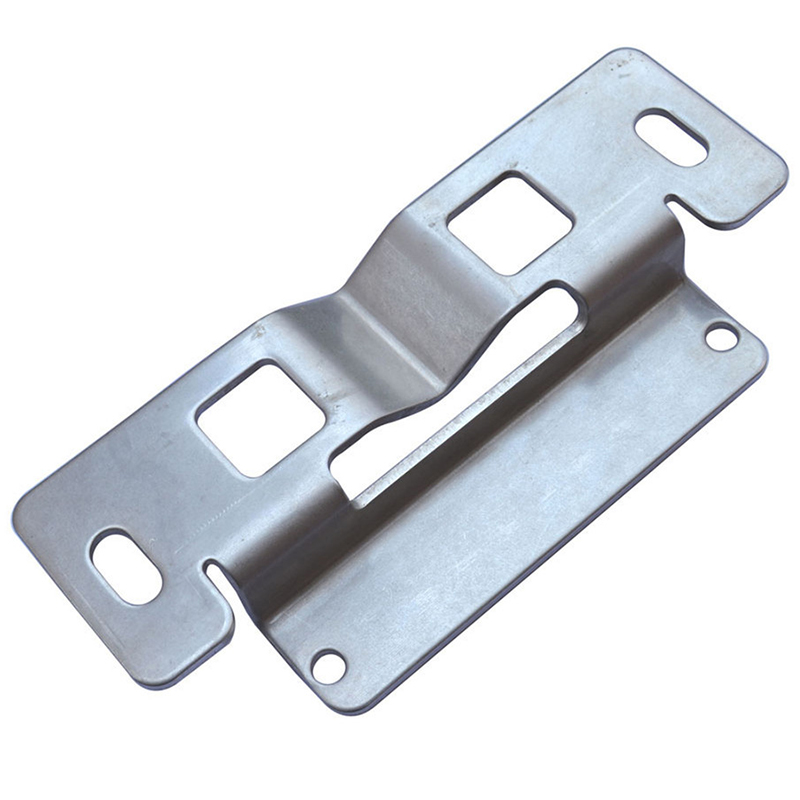

I-punching die sisixhobo sokuvelisa ukuhlukana okanye ukuguqulwa kwezinto zeshidi, eziqulethwe ngamacandelo amabini: ukufa okuphezulu kunye nokufa okuphantsi.Ifa eliphezulu limiselwe kwisilayidi somatshini wokubhoboza kwaye lihamba linyuka lisihla kunye nesilayidi, ngelixa ukufa okuphantsi kugxininiswe kwitafile yomatshini wokubhoboza.Kukufa okuyimfunekoimveliso yesitampu.Ngokwesakhiwo se-die, inkqubo inokwahlulwa ibe yi-stamping elula, i-stamping eqhubekayo kunye ne-compound stamping.

4. Ukuhlelwa ngokweenkqubo ezisisiseko:

Ngokwenkqubo esisiseko, isitampu sahlulwe ngokweenkqubo ezininzi ezisisiseko ezifana nokuwisa, ukubethelwa, ukugoba kunye nokuzoba nzulu.

5. Ukuhlelwa ngokwezinto zestamping workpiece:

Iipleyiti ezisetyenziswa ngokuqhelekileyo ziyi-alloy ye-titanium ephantsi, i-carbon steel, insimbi engenasici, i-aluminium, ubhedu kunye ne-alloys yayo, njl. Zineplastiki ephezulu kunye nokuchasana kwe-deformation ephantsi, kwaye ifanelekile kwi-cold stamping processing.

Ixesha lokuposa: May-29-2023