Kupondaponda ndi njira yopangira yomwe imadalira makina osindikizira ndikufa kuti agwiritse ntchito mphamvu zakunja ku mbale, mizere, mapaipi ndi mbiri kuti apange mapindikidwe apulasitiki kapena kupatukana kuti apeze zogwirira ntchito za mawonekedwe ndi kukula kwake.Malingana ndi zochitika zosiyanasiyana za ndondomeko, ndondomeko ya stamping ili ndi njira zosiyanasiyana.Tiyeni tifotokoze mwachidule mitundu yanjizitsulostamping ndondomekopa zotsatirazi.

1. Malinga ndi workpiece yomalizidwa kugawanitsa:

Njira yosindikizira imatha kugawidwa m'magulu awiri molingana ndi chogwirira ntchito chomalizidwa: njira yolekanitsa ndi kupanga mapangidwe (komanso kugawidwa kukhala kupinda, kujambula ndi kupanga).

2.Malinga ndi kutentha kwakupondapondakugawa:

Pali mitundu iwiri ya kupondaponda, kupondaponda kozizira komanso kupondaponda kotentha, malinga ndi momwe kutentha kumakhalira panthawi yopondaponda.Izi zimadalira mphamvu, pulasitiki, makulidwe, digiri ya mapindikidwe ndi mphamvu ya zipangizo zakuthupi, ndi zina zotero.

3. Gulu molingana ndi kapangidwe kakekufa nkhonya:

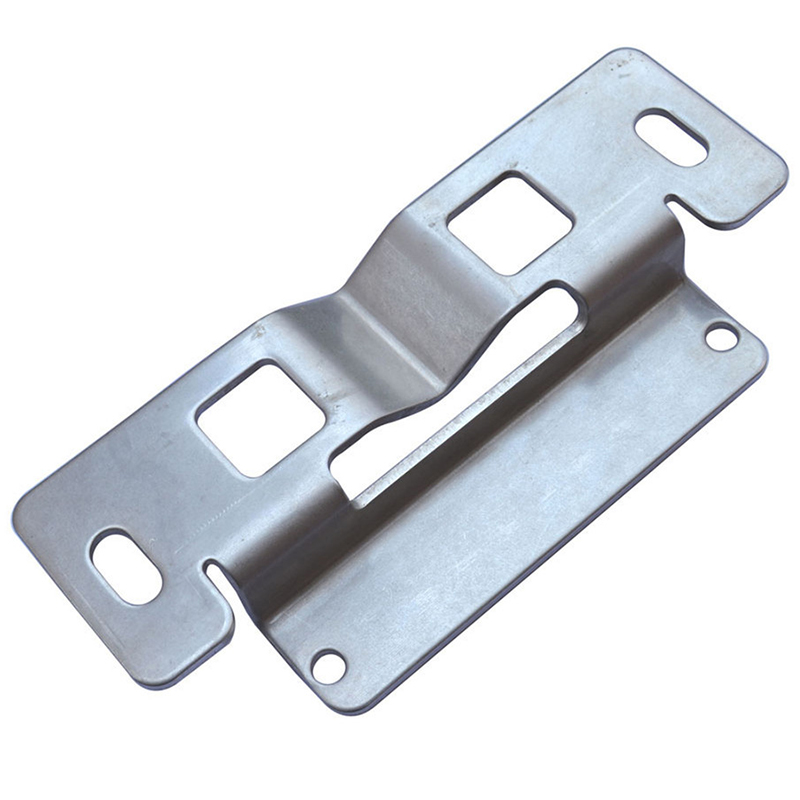

The nkhonya kufa ndi chida kubala kulekana kapena mapindikidwe a pepala zakuthupi, umene uli mbali ziwiri: chapamwamba kufa ndi m'munsi kufa.Kufa kwapamwamba kumayikidwa pa slide ya makina okhomerera ndikusunthira mmwamba ndi pansi ndi slide, pamene kufa kwapansi kumayikidwa patebulo la makina okhomerera.Ndi kufa kofunikirakupanga masitampu.Malinga ndi kapangidwe ka kufa, njirayo imatha kugawidwa kukhala masitampu osavuta, kupondaponda kosalekeza komanso kupondaponda pawiri.

4. Gulu motengera njira zoyambira:

Malinga ndi ndondomeko yoyambira kupondaponda kumagawidwa m'njira zingapo zofunika monga dontho, kukhomerera, kupindika ndi kujambula mozama.

5. Gulu molingana ndi zinthu za stamping workpiece:

Ma mbale omwe amagwiritsidwa ntchito kwambiri ndi otsika titaniyamu aloyi, carbon zitsulo, zitsulo zosapanga dzimbiri, aluminiyamu, mkuwa ndi aloyi ake, etc. Iwo ali pulasitiki mkulu ndi otsika mapindikidwe kukana, ndipo ndi oyenera ozizira masitampu processing.

Nthawi yotumiza: May-29-2023